I. Product introduction

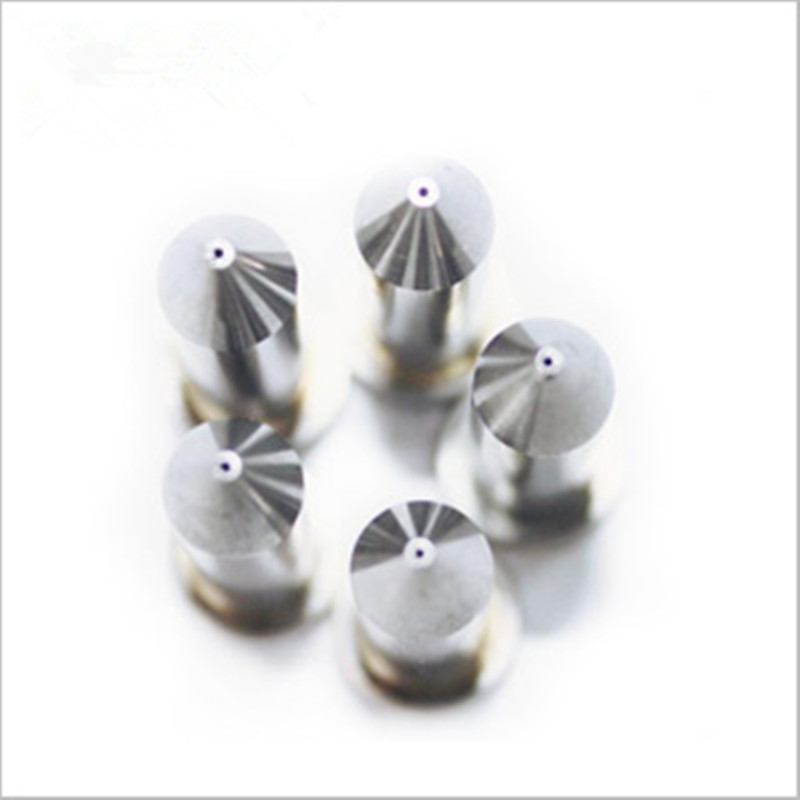

A nozzle is a device designed to control the direction or flow of special gas (especially to increase the speed) when an object enters (or exits) a closed cavity or pipe. With larger orifices, a better flow rate allows for increased efficiency in proper applications. In terms of nozzles, cemented carbide nozzles are the most durable and cost-effective. The cemented carbide nozzle is processed by precision machining. The bending resistance reaches 2300N/mm, and the hardness reaches HRA90 degrees. Tungsten carbide has exceptional wear resistance due to its high hardness, thus the nozzle’s hole size and height will always stay the same for a rather long time.

II.Grade for Carbide Nozzle

| GRADE | ISO CODE | DENSITY | HARDNESS | Bending Strength |

| g/cm3 | HRA | MPa | ||

| YG6 | K20 | 14.95 | 90.5 | 2200 |

| YG6X | K10 | 14.95 | 92.0 | 2000 |

| YG8 | K20 | 14.65-14.85 | 90.0 | 2600 |

| YT5 | P30 | 13.05 | 90.5 | 2200 |

| YT14 | P20 | 11.50 | 91.50 | 2000 |

III.Advantages of ZZ Old Craftsman Carbide Nozzle

- Brilliant features. Corrosion resistance, long service life, excellent performance with low cost, good wear resistance, and precise grinding.

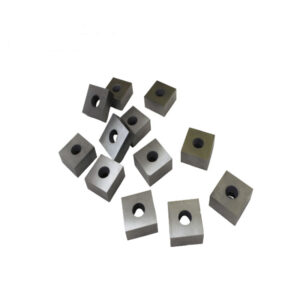

- Customization. Design, size or even grade can be adjusted according to customer’s detailed requirements.

- Superior value. Despite of slightly higher initial price, our carbide nozzles can save you a lot for their longer service life.

- Quality guarantee. With complete production line and advanced equipment, products’ quality is rigorously inspected and the test results are available if needed.

IV.Application of Carbide nozzle

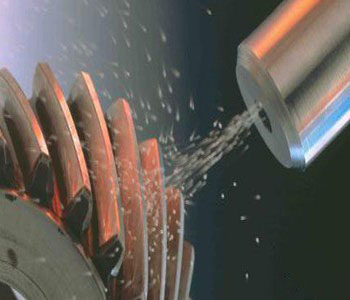

Carbide nozzles are highly sought after for their exceptional performance and resilience. They have been used in a variety of industrial applications, from sandblasting to shot peening and water jet cutting, where abrasive materials or high-pressure liquids require robust solutions. The wear resistance of carbide is ideal for withstanding the aggressive force that results when directing an abrasive stream at a surface such as rust or paint coatings being removed during sandblasting operations.

In shot peening, carbide nozzles are used to create a high-velocity stream of small metal balls or pellets that impact the surface of a metal part, creating compressive stress to improve its fatigue life. Carbide nozzles are preferred in this application due to their ability to withstand the high-impact forces involved.

In water jet cutting, carbide nozzles are used to focus a high-pressure stream of water onto a material, cutting through it with extreme precision. The high temperature and corrosion resistance of carbide nozzles make them suitable for use in this application, as they can withstand the harsh conditions of the cutting process.

Overall, carbide nozzles are versatile and widely used in many industrial applications where high performance, durability, and precision are essential.