I.Carbide Grade for Carbide Liner

| Grade | Nickel Content

Ni% |

Density

g/cm3 |

Hardness

(HRA) |

T.R.S

(MPa) |

Grain Size

(um) |

| YN6 | 6.0 | 14.82 | 92.0 | 2150 | 0.8 |

| YN8 | 8.0 | 14.80 | 91.5 | 2200 | 0.8 |

| YN10 | 10.0 | 14.60 | 90.5 | 2350 | 0.8 |

| YN14 | 14.0 | 14.15 | 88.8 | 2300 | 1.0 |

| YN20 | 20.0 | 14.10 | 88.5 | 2400 | 0.8 |

| YN10S | 10.0 | 14.65 | 92.0 | 2500 | 0.6 |

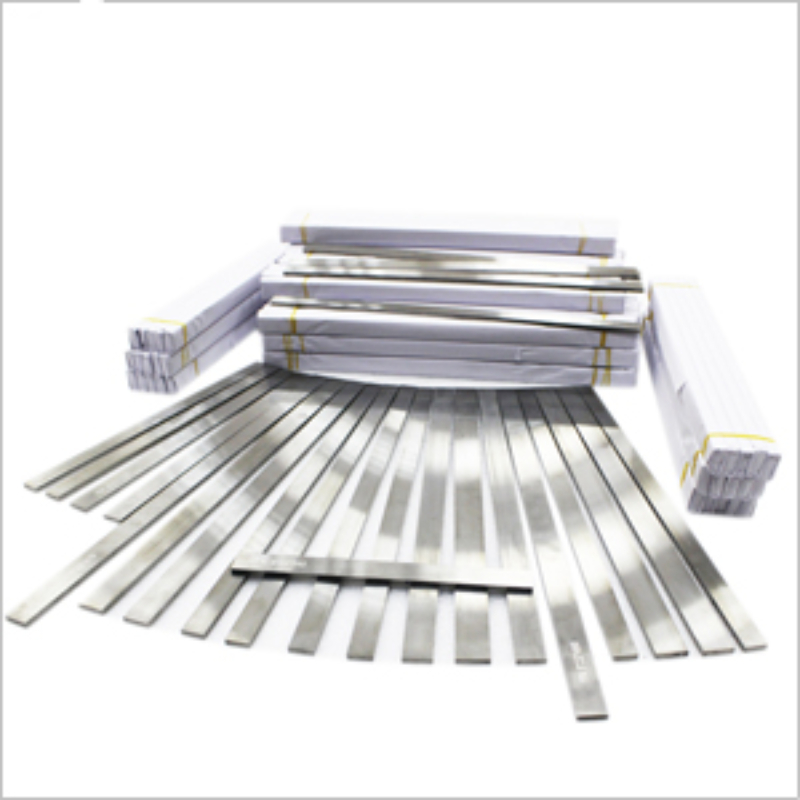

II. Size information for Carbide Liner

| Length

(0/+5)mm |

Width

(0/+5)mm |

Thickness

(+0.5/+0.6)mm |

| 100-200 | 20/22/25 | 4/5 |

| 200-300 | 20/22/25/30 | 4/5 |

| 300-400 | 20/22/25/30 | 4/5 |

| 400-500 | 20/22/25/30 | 4/5 |

| 500-600 | 20/22/25 | 4/5 |

| 600-700 | 22/21/25 | 4/5 |

III. Advantages of old craftsman carbide liners for ceramic mold:

- Having been produced the non-magnetic carbide grade for more than 10 years, we possess the comprehensive knowledge on products.

- Communicate with client closely, knowing the detailed requirement from the onsite usage.

- Use special glue technique, and control tolerance strictly.

- Produce 100% based on customer design and drawing, easy for installation.

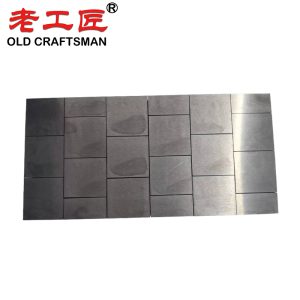

IV. Application of carbide liners for ceramic mold:

Using carbide with steel for the ceramic mold is a new development. The new model includes a frame, multiple female molds composed of multiple side plates are fixed on the inner wall of the frame, and the side plates composed of cemented carbide and a steel substrate supporting the cemented carbide are placed on the molding surface that is in contact with the ceramic floor and wall tiles. Or the pressure surface is fixed with cemented carbide. It solves the problems of low hardness and short service life of ceramic floor and wall tiles made of alloy steel or high-speed tool steel.

We are now mainly producing and exporting these liners to Asia, Europe. All are produced according to customer’s design. If you have any doubt on your design, welcome to contact us. We can give you professional suggestions.