High-Abrasion Resistant

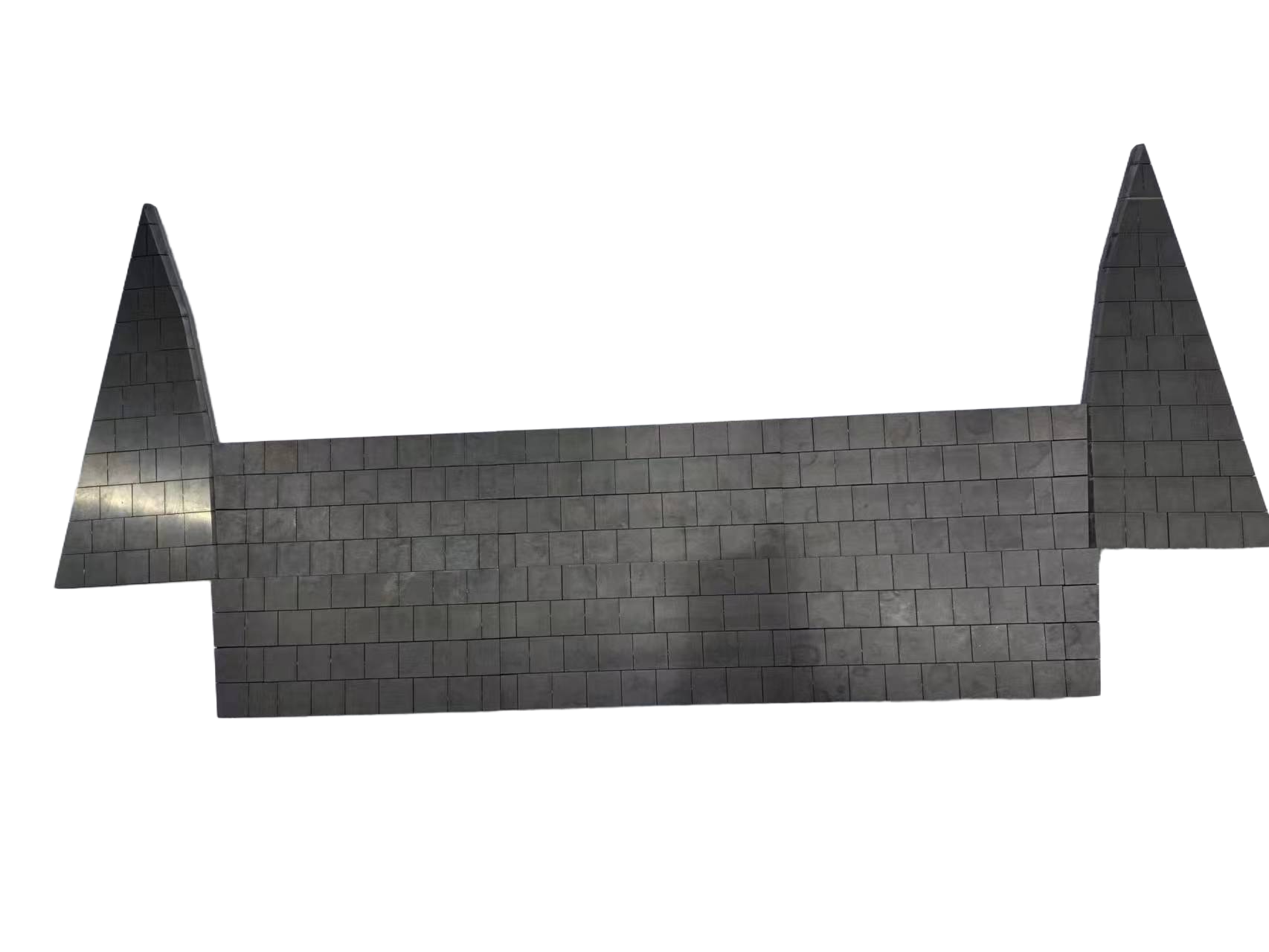

Tungsten carbide wear plate Factory

Up to 100 Weeks Without Replacement

Enhance your mining efficiency and reduce equipment downtime with our Custom Carbide Wear Plates.– your key to longer-lasting machinery and lower labor costs