In the mining industry, crushers play a pivotal role in efficient material handling and ore processing. Whether during primary crushing or more refined post-processing stages, the efficient operation of crushers directly impacts production efficiency and resource utilization. As mineral resources are continually extracted, variations in ore hardness, texture, and working conditions place greater demands on crushers. Therefore, ensuring the stability and durability of crushers is a key factor in the mining process.

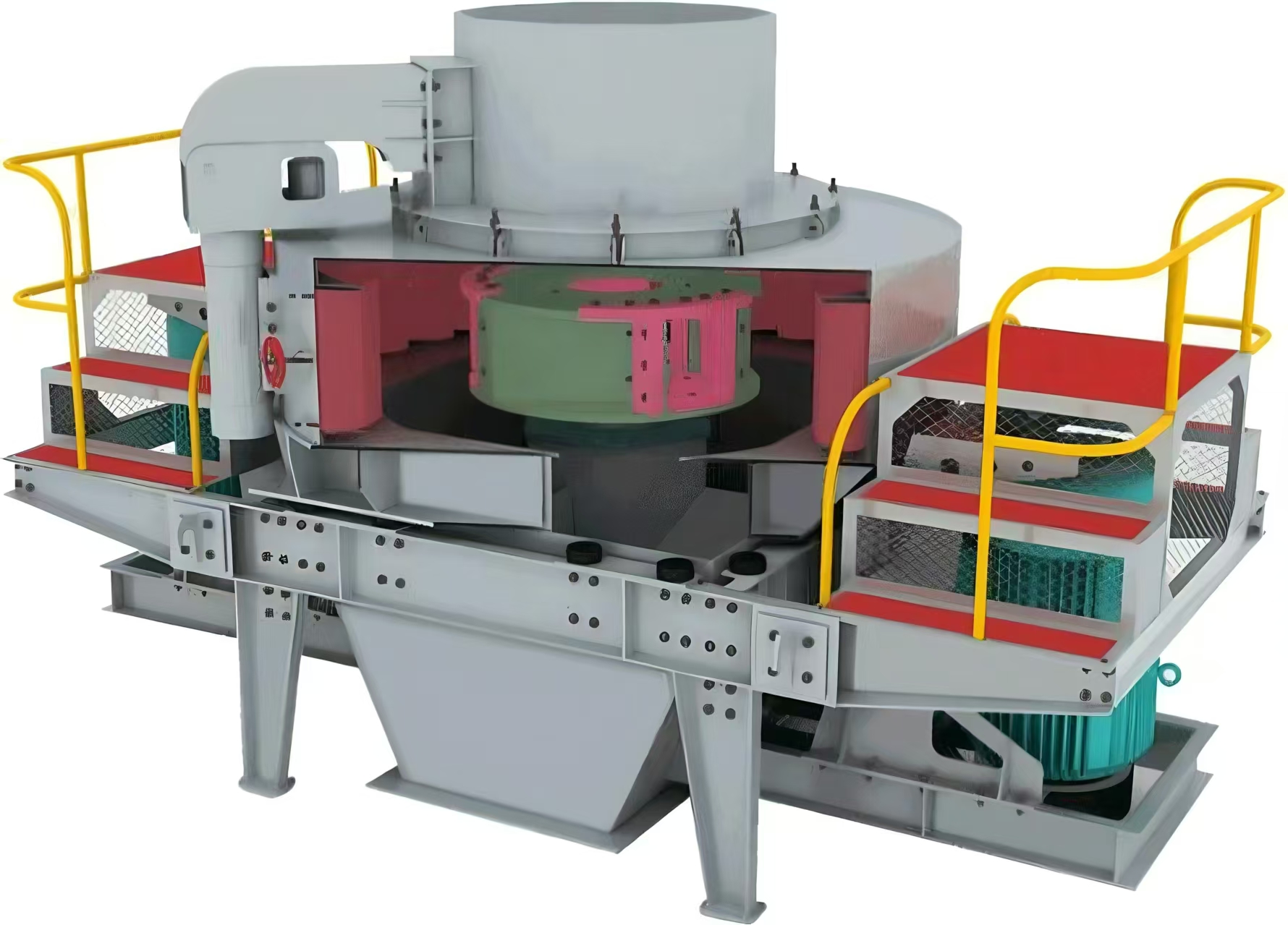

Impact crushers and hammer crushers are two commonly used types of crushers, each serving different stages of the crushing process. Impact crushers are typically employed in finer crushing stages, especially when the final product requires a precise cubic shape. Material is accelerated to high speeds by a rapidly rotating rotor and is crushed through impact. On the other hand, hammer crushers are more commonly used in coarse and medium crushing stages, where a rotating rotor and impact plates break down the material into smaller particles. Despite differences in working principles, both crushers operate under high impact and abrasion conditions, necessitating the use of highly durable and impact-resistant liner materials. Tungsten carbide wear liners, known for their exceptional hardness and wear resistance, emerge as the ideal solution for these demanding applications. With its superior performance, tungsten carbide effectively enhances crusher efficiency, extends equipment lifespan, and minimizes maintenance, ensuring reliable and efficient operation in harsh environments.

What is tungsten carbide and Its Advantages?

Tungsten carbide is a compound composed of tungsten and carbon. Its chemical formula is WC, and its English name is Tungsten Carbide. It is also often referred to as Carbide (in fact, carbide is a general term for carbides). Tungsten carbide has an extremely high hardness, with a Mohs hardness of 8.5-9, and a melting point of 2870°C. It also has low electrical resistance and is often used as a cutting tool material (can cut stainless steel), to make drill bits , and high-hardness armor or armor-piercing projectile cores.

There are many kinds of lining materials commonly used in the market, but they all have some shortcomings.However, unlike other common materials, our tungsten carbide material has incomparable advantages.

Tungsten carbide is renowned for its exceptional hardness, wear resistance, and impact strength, making it the material of choice for crusher liners. Crushers are subjected to high-frequency impacts, friction, and wear, especially in primary crushing stages. Tungsten carbide’s hardness, nearly equivalent to diamond, allows it to easily withstand these extreme conditions. In addition to its hardness, tungsten carbide also offers the following advantages:

Outstanding Wear Resistance

Tungsten carbide liners are capable of enduring prolonged wear without degrading quickly. This significantly reduces downtime due to wear and enhances operational efficiency.

Exceptional Impact Strength

Crushers operate under intense impact forces, especially in primary crushing. Tungsten carbide’s ability to withstand these forces without cracking or deforming ensures consistent performance even in the harshest conditions.

Extended Service Life

Due to its superior wear and impact resistance, tungsten carbide liners last significantly longer than traditional liner materials such as steel or cast iron. This reduces the frequency of liner replacements and lowers overall maintenance costs.

Improved Crushing Efficiency

Tungsten carbide liners optimize the crushing process, reducing energy consumption and enabling the crusher to operate at higher efficiency, thereby boosting production and lowering energy costs.

Reliability and Stability

Tungsten carbide is chemically and thermally stable, unaffected by high temperatures, corrosion, or oxidation. This ensures that the crusher continues to operate reliably, even under extreme conditions.

Thanks to these unique qualities, tungsten carbide liners have become the preferred choice for impact crushers and hammer crushers, enhancing equipment performance while reducing overall operational costs and ensuring efficient and reliable production.

Why choose our ZZ Old Craftsman Precision Alloy Co., Ltd.?

As crusher technology continues to evolve, the demands on liner materials are becoming more stringent. To meet these needs, our ZZ Old Craftsman Precision Alloy Co., Ltd. leverages over 30 years of industry experience to provide high-performance wear solutions, particularly in the design and manufacturing of tungsten carbide liners. We focus not only on product quality and technological innovation but also on delivering exceptional value to our customers, ensuring the best return on investment while improving equipment efficiency and reducing operational costs.

With a solid technical foundation, our company has accumulated extensive experience in hard alloy materials, enabling us to provide precise designs and manufacturing tailored to the specific needs of our customers. This ensures that every tungsten carbide liner ,we produce delivers optimal performance, suited to different crusher conditions. Additionally, our customized services cater to the unique specifications of various crusher models, operating environments, and load conditions, guaranteeing the smooth and efficient operation of equipment.

One of our key strengths is our cost-effectiveness. Through meticulous production processes and optimized material selection, we minimize production costs, allowing customers to enjoy high-quality tungsten carbide liners at a reasonable price. Compared to traditional materials, tungsten carbide liners offer a longer service life and lower maintenance costs, enabling clients to benefit from extended operational uptime and reduced liner replacement expenses.

Moreover, our company is committed to excellence in material selection and production techniques. We use top-tier tungsten carbide materials and advanced vacuum brazing technology to ensure the wear resistance and impact strength of our liners. Each liner undergoes strict quality testing to ensure superior performance in real-world applications. This dedication to quality has earned us a solid reputation in the industry and the trust of our clients.

Through continuous innovation and research, we continually enhance our products’ performance, helping customers improve crusher efficiency, reduce downtime, and lower operating costs. By choosing us for your liner needs, you gain access to world-class technical support, tailored services, high-performance products, and exceptional value, ensuring that your equipment runs reliably in even the most challenging conditions.

Conclusion

In the mining industry, selecting the right crusher liner is crucial to ensuring efficient operation and long-term stability. Tungsten carbide liners, with their outstanding properties, are the ideal choice for crushers, enhancing equipment performance, extending service life, and reducing maintenance costs. ZZ Old Craftsman Precision Alloy Co., Ltd., with over 30 years of experience and expertise, is committed to providing customers with customized, high-quality wear solutions, helping businesses stand out in an increasingly competitive market. By choosing us, you will benefit from top-tier products and services, ensuring that your crushers operate at peak performance.

If you want to know more, please contact us.