In a conveyor system, belt cleaner scraper blades are a critical component to ensure the smooth operation of the conveyor. The primary role of these scrapers is to remove residual materials from the belt surface, preventing build-up that could lead to belt misalignment, wear, or reduced production efficiency. The secondary cleaner scraper blades, in particular, handle the stubborn material left behind after primary cleaning, directly affecting the cleanliness of the belt and the lifespan of the equipment. Therefore, it is crucial to choose a blade with high wear resistance and corrosion resistance, and this is where tungsten carbide material stands.

Why is tungsten carbide belt scraper more suitable than ordinary materials?

Before delving into vacuum brazed tungsten carbide blades, let’s examine the performance of other common blade materials on the market. Steel, rubber, polyurethane, stainless steel, and ceramics are popular choices, but they each have limitations in practical applications:

Mild Steel: Has poor wear resistance and a short lifespan, requiring frequent replacements, which increases operational costs.

Rubber or Polyurethane: These materials are flexible, but they struggle with sticky materials, and their cleaning effectiveness is insufficient.

Stainless Steel: While highly corrosion-resistant, it wears quickly in high-friction environments, reducing its lifespan.

Ceramics: Although hard, ceramics are brittle and can easily break under high-impact conditions.

While each of these materials has its pros and cons, none can meet the high standards of wear resistance, corrosion resistance, and durability simultaneously. Tungsten carbide blades, on the other hand, offer outstanding performance and effectively fill this market gap.

Why Tungsten Carbide Has Become the Revolutionary Material for Cleaner scraper Blades?

Tungsten carbide (also known as hard alloy) blades have emerged as a revolutionary choice for belt cleaners due to the following key advantages:

Superb Wear Resistance: Tungsten carbide’s hardness far exceeds that of mild steel, making it highly resistant to abrasion and impact, keeping the blades sharp for longer.

Excellent Corrosion Resistance: Tungsten carbide performs well in humid or chemically corrosive environments, maintaining stability and durability.

Long Lifespan: The lifespan of a tungsten carbide blade is typically over three times longer than that of conventional materials, significantly reducing maintenance frequency and downtime.

High Temperature Performance: Tungsten carbide retains its properties even in extreme temperatures, making it adaptable to a wide range of challenging working conditions.

Why Choose ZZ Old Craftsman’s Vacuum Brazed Tungsten Carbide secondary belt cleaner scraper?

At ZZ Old Craftsman, we don’t just provide high-quality tungsten carbide blades—we offer advanced craftsmanship and technology that sets our products apart:

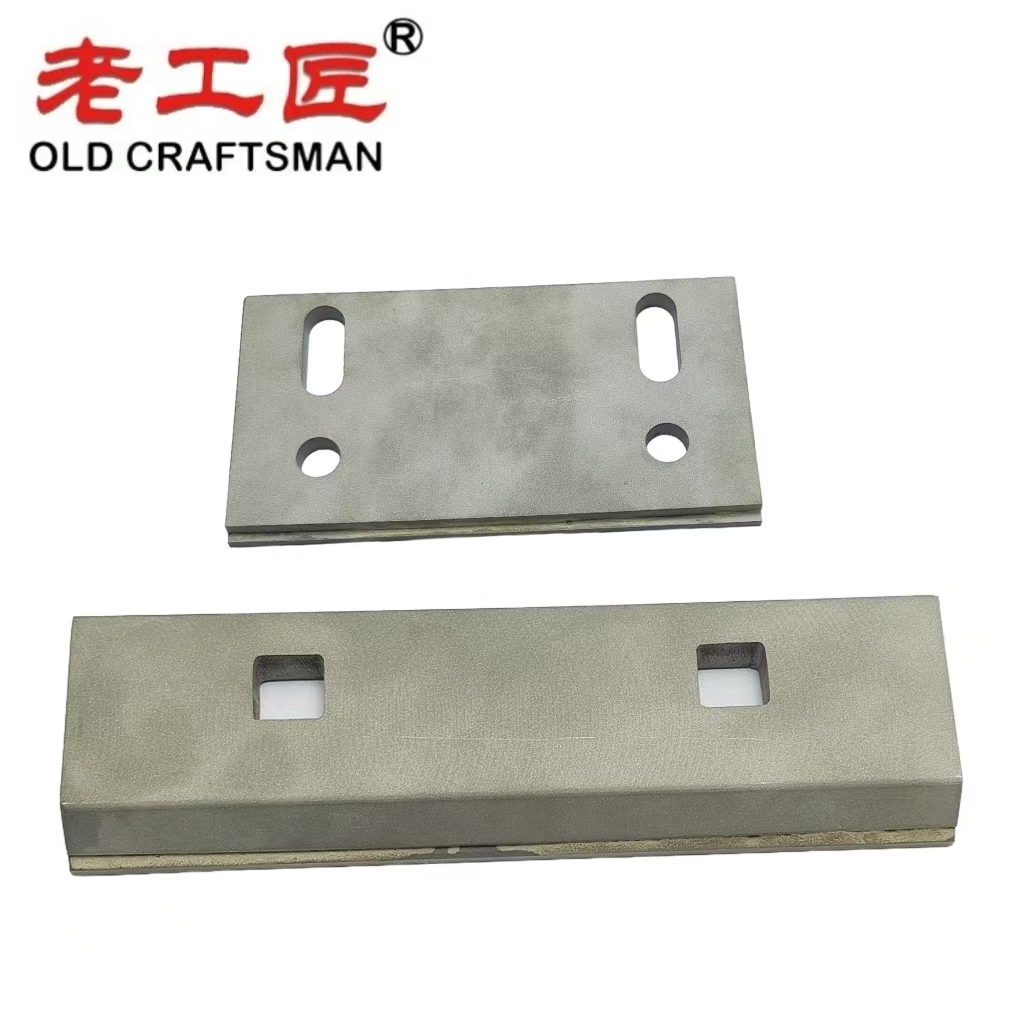

- Advanced Technology: We use cutting-edge vacuum brazing technology to ensure a strong bond between the tungsten carbide and the base material, resulting in blades that are both robust and durable.

- Strict Quality Control: Each blade undergoes rigorous testing to ensure exceptional performance under demanding working conditions.

- Custom Solutions: Our technical team can design the most suitable solution for your specific needs, addressing complex operational environments.

- Cost-Effective: By optimizing production processes and supply chain management, we offer competitive pricing without compromising on quality.

Choose ZZ Old Craftsman for a More Efficient Future

A high-quality belt cleaner blade not only improves equipment efficiency but also reduces operational costs by minimizing downtime and maintenance. By choosing ZZ Old Craftsman’s vacuum brazed tungsten carbide blades, you’ll get the dual assurance of top-tier performance and reliability. Contact us today to learn more about our products or customized solutions and let us help you achieve a more efficient, sustainable future!

A mining conveyor belt carbide scraper designed for harsh and corrosive environments typically employs high-performance materials such as abrasion-resistant alloyed steel or advanced corrosion-resistant alloys, including duplex stainless steel and austenitic stainless steel.

These corrosion-resistant metals exhibit excellent corrosion resistance across a wide range of aggressive conditions, primarily due to their carefully controlled chemical composition: a relatively low carbon content combined with high chromium levels that promote the formation of a stable, self-healing chromium oxide passive layer, even at room temperature. Additional alloying elements are often incorporated in small amounts to further enhance performance.

Duplex stainless steel, in particular, offers an outstanding combination of high tensile strength, superior resistance to stress corrosion cracking, and exceptional abrasion resistance, making it ideal for heavy-duty mining applications exposed to wet, acidic, or chloride-rich environments. Compared to conventional steels, these high-resistance steel alloys deliver significantly longer service life and greater cost-effectiveness by minimizing downtime and replacement frequency in highly corrosive environments, while maintaining the necessary mechanical properties to withstand constant impact and scraping forces on conveyor belts.

Read related articles

How Many Types of Scrapers Are in a Conveyor Belt?

Why Choose Carbide Vacuum Brazed Wear Liners for HPGR?

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding