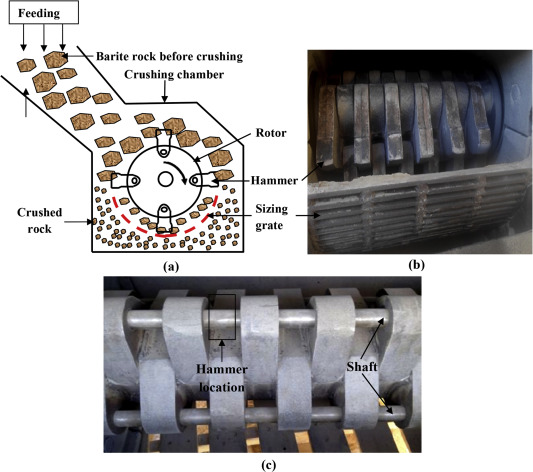

When comparing carbide crusher hammers (e.g., tungsten carbide, WC-based) and high chrome hammers (e.g., high chromium cast iron, 15-30% Cr) specifically for abrasion resistance, carbide hammers are generally superior. Here’s a focused analysis:

1. Material Properties Related to Abrasion Resistance

- Carbide Hammers (WC-Based):

- Hardness: Tungsten carbide has an exceptional hardness of 1200-1400 HV (Vickers), far exceeding most materials. This is due to WC’s near-diamond-like structure.

- Abrasion Mechanism: WC resists wear from hard, abrasive particles (e.g., silica, quartz) because its hardness surpasses that of most abrasives encountered in crushing (e.g., silica’s hardness is ~1000 HV).

- Structure: Typically applied as hard-facing or inserts on a steel base, with a high volume fraction of WC particles (70-90%) in a cobalt binder.

- High Chrome Hammers:

- Hardness: High chromium cast iron achieves 600-700 HV, thanks to hard chromium carbides (Cr₇C₃, ~1200 HV) embedded in a martensitic or austenitic matrix.

- Abrasion Mechanism: The Cr₇C₃ carbides provide good resistance to abrasion, but the softer matrix (300-500 HV) wears faster, reducing overall performance against highly abrasive materials.

- Structure: A homogeneous alloy with carbide particles distributed throughout, typically 20-35% carbide by volume.

2. Abrasion Resistance Comparison

- Carbide (WC):

- Performance: WC’s extreme hardness ensures minimal material loss against abrasive particles. It excels in conditions with fine, hard abrasives like silica, sand, or coal ash.

- Lab Evidence: In ASTM G65 dry sand abrasion tests, WC-Co hard-facing typically shows mass loss of ~0.1 g, reflecting its superior resistance.

- Field Example: In coal crushing with 15% silica, WC hammers might last 9-12 months due to their ability to withstand continuous scratching and grinding.

- High Chrome:

- Performance: The chromium carbides resist abrasion well, but the softer matrix erodes faster, exposing carbides that can then break away. It’s effective but less durable against extreme abrasives.

- Lab Evidence: In the same ASTM G65 test, high chrome might lose ~0.3-0.4 g of mass, 3-4 times more than WC.

- Field Example: In the same coal crushing scenario, high chrome hammers might last 4-6 months, wearing out quicker as the matrix degrades.

3. Key Factors in Abrasion Resistance

- Hardness Differential: WC’s 1200-1400 HV outclasses high chrome’s 600-700 HV overall, and even Cr₇C₃ carbides (~1200 HV) are less effective due to lower volume fraction and matrix vulnerability.

- Carbide Volume: WC hammers have a higher concentration of hard phases (70-90% vs. 20-35% in high chrome), providing a denser barrier against abrasive wear.

- Binder/Matrix Effect: Cobalt in WC-Co (6-12%) is tougher than high chrome’s matrix, maintaining structural integrity longer under abrasive attack.

4. Practical Outcome

- Carbide Wins: For pure abrasion resistance, carbide hammers outperform high chrome hammers significantly. They’re the better choice in highly abrasive environments, such as crushing coal with high silica content, quartz-rich ores, or sandstone, where scratching and grinding dominate wear.

- High Chrome Limitation: While high chrome is abrasion-resistant, it’s less effective against extreme abrasives due to matrix wear, making it a secondary option in such conditions.

For abrasion resistance alone, carbide crusher hammers (WC-based) are better than high chrome hammers. Their superior hardness and higher carbide content make them more durable against abrasive materials, often achieving 2-3 times the lifespan in abrasive-heavy applications.

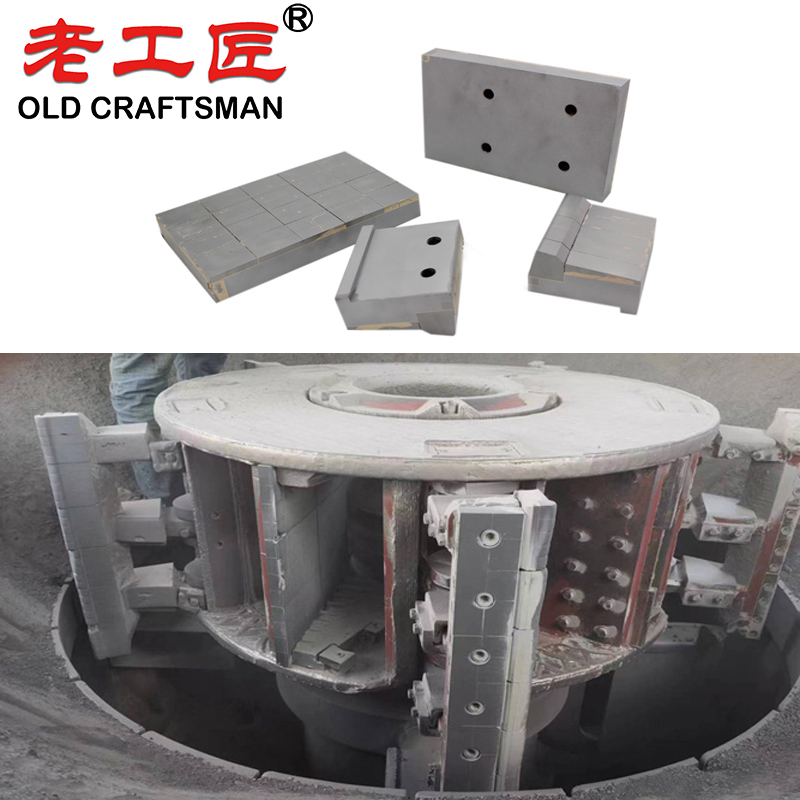

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide crusher hammer and make your crusher hammer use life is tens of times longer than before! We specialize in providing customized carbide solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work