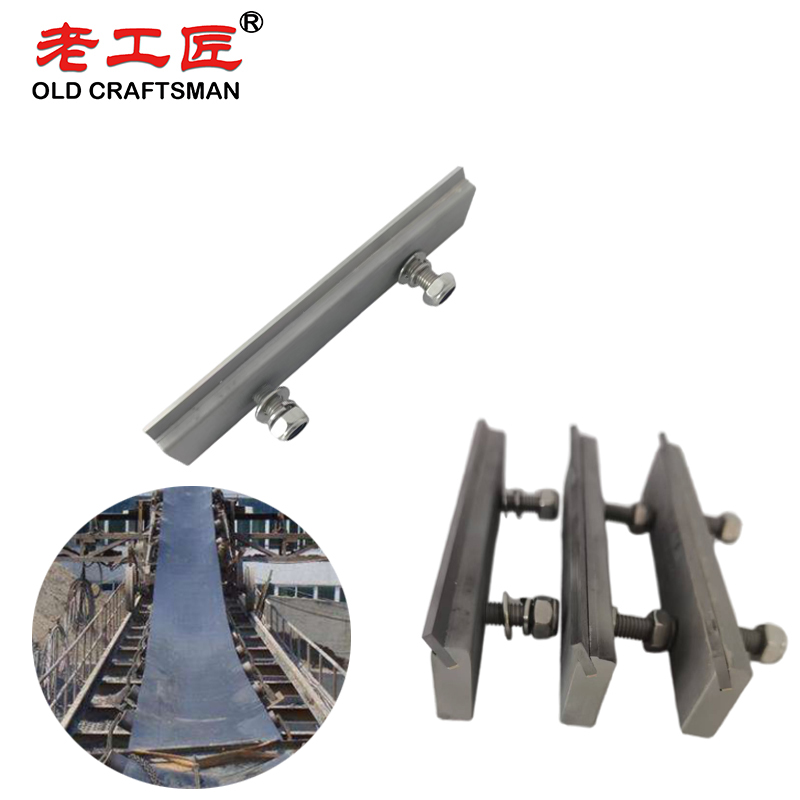

Tungsten carbide scrapers are recommended for conveyor belts due to their superior performance in heavy-duty applications. Here’s why:

1.Exceptional Durability: Tungsten carbide is extremely hard and wear-resistant, lasting significantly longer than materials like polyurethane or rubber. It can withstand abrasive materials and harsh conditions, reducing replacement frequency and maintenance costs.

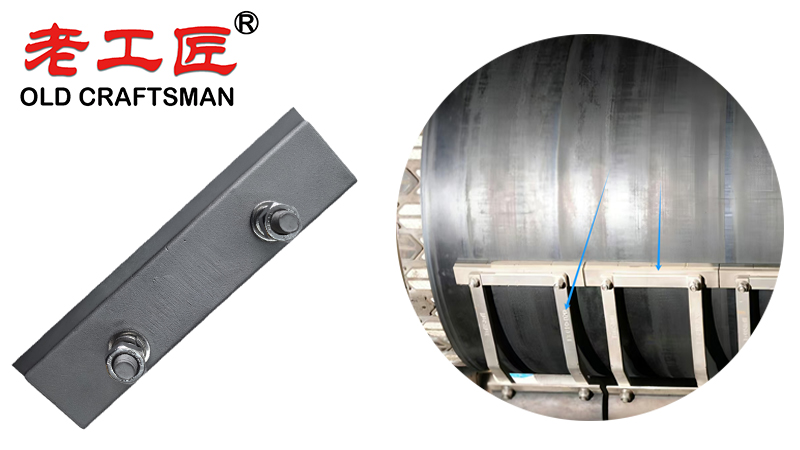

2.Superior Cleaning Efficiency: These scrapers effectively remove sticky or resilient materials, minimizing carry-back and preventing material buildup. This ensures smoother operation and reduces downtime for cleaning.

3.Cost-Effectiveness Over Time: Despite a higher initial cost, tungsten carbide blades have a lower lifetime cost due to their longevity and reduced maintenance needs, making them economical for high-wear applications.

4.Versatility in Harsh Conditions: They perform well with highly abrasive materials like ore, sand, or asphalt, and are suitable for belts handling heavy loads or operating at high speeds.

5.Compatibility with Modern Systems: Advances in design make some tungsten carbide blades compatible with mechanically spliced belts, expanding their usability without risking belt damage.

6.Enhanced Safety and Efficiency: By preventing material spillage and buildup, these scrapers reduce workplace hazards (e.g., slips or equipment damage) and improve conveyor efficiency, boosting productivity.

Considerations: Tungsten carbide scrapers are best for new or undamaged belts, as they can potentially damage worn or mechanically fastened belts if not properly designed. For less abrasive or sensitive applications, polyurethane might be more forgiving

In summary, tungsten carbide scrapers are recommended for their durability, cleaning efficiency, and long-term cost savings, especially in demanding industrial settings where abrasive materials are common. Always ensure the scraper is suited to the belt type and application for optimal results.

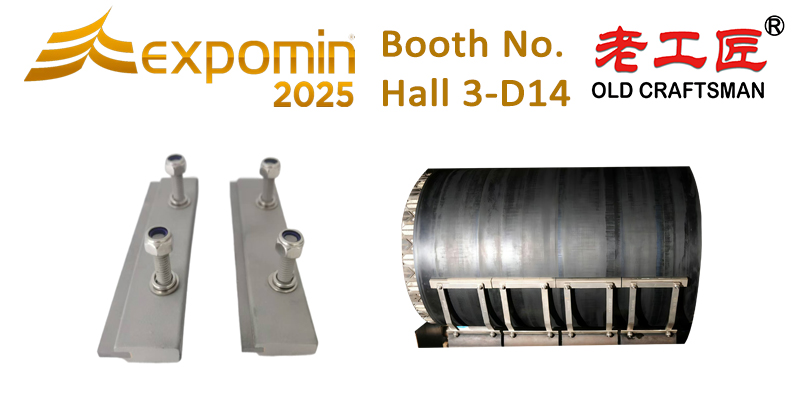

Our tungsten carbide wear solutions are widely used in crushing iron ore, copper ore, magnesite, tungsten ore, granite, basalt, limestone, coal, and other ores. We look forward to welcoming you at Expomin 2025 and exploring how our tungsten carbide products can add value to your operations.

To know more about our solutions, visit www.zzcraftsman.com or contact Journey directly at 0086 15273334558. We look forward to meeting you in Santiago and exploring how our solutions can drive your success at EXPOMIN 2025!

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work