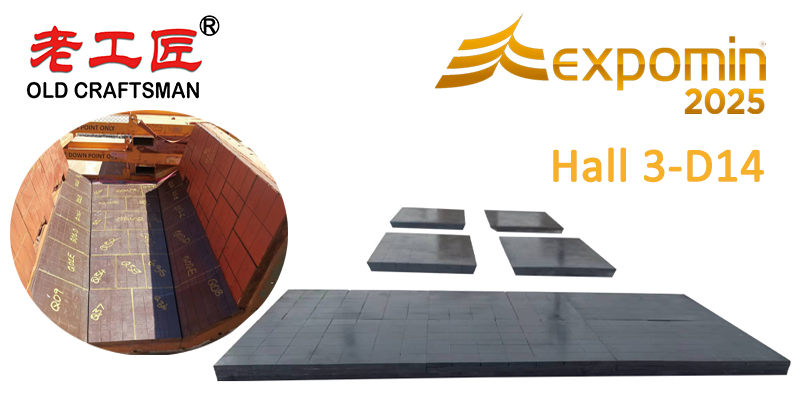

EXPOMIN 2025 In Chile – Why we do recommend conveyor belt tungsten carbide scraper

Tungsten carbide scrapers are recommended for conveyor belts due to their superior performance in heavy-duty applications. Here’s why: 1.Exceptional Durability: Tungsten carbide is extremely hard and wear-resistant, lasting significantly longer than materials like polyurethane or rubber. It can withstand abrasive materials and harsh conditions, reducing replacement frequency and maintenance costs. 2.Superior Cleaning Efficiency: These scrapers […]

EXPOMIN 2025 In Chile – Why we do recommend conveyor belt tungsten carbide scraper Read More »