How to improve the efficiency of vSI crusher? Choosing right hammer is the key

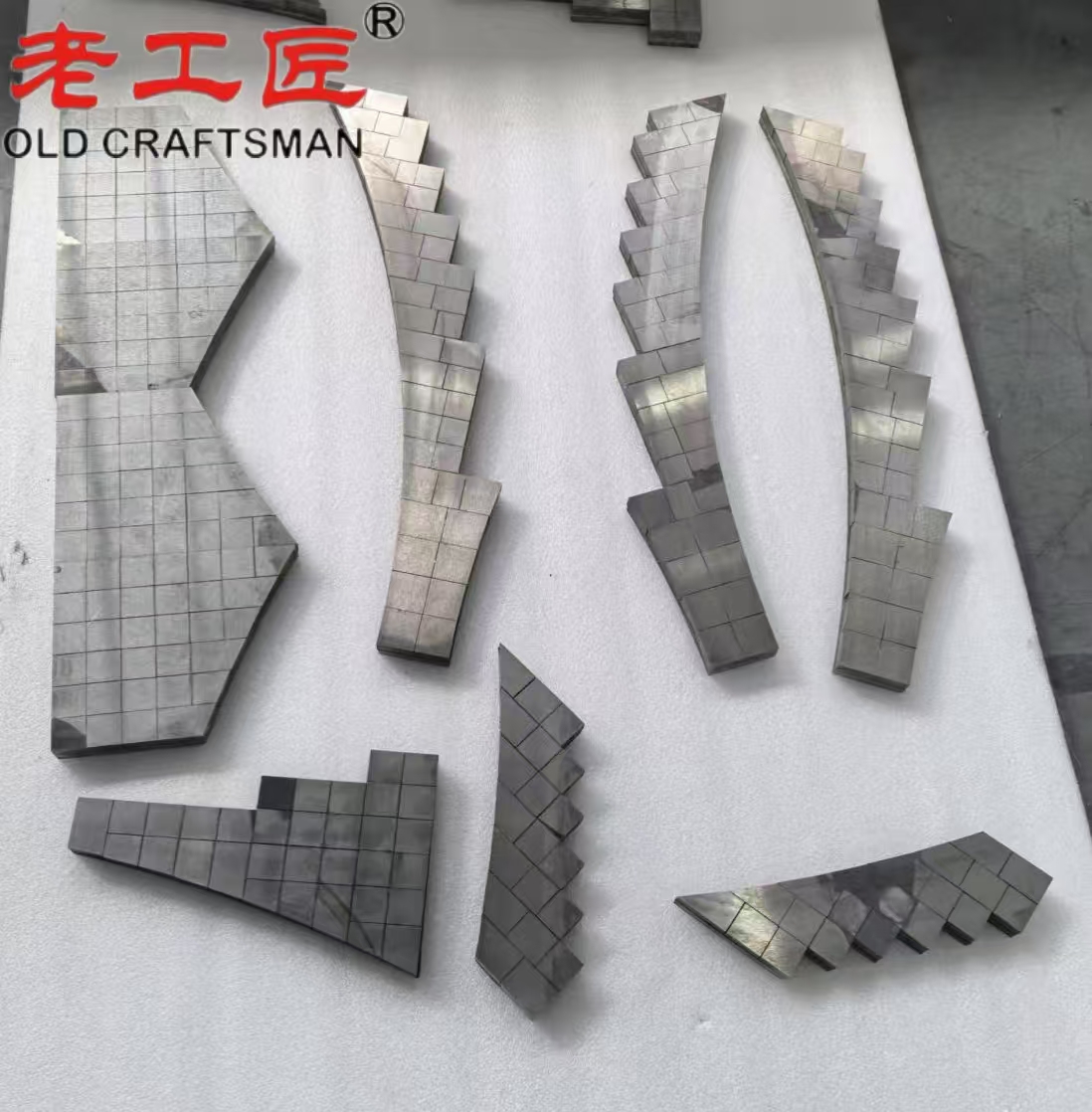

The rotor of the hammer crusher is one of the core components of the hammer crusher. It is mainly responsible for striking and impact crushing the materials entering the crushing chamber. The rotor is equipped with several hammers, which are usually made of high-hardness wear-resistant materials to withstand the high-intensity impact and wear of the […]

How to improve the efficiency of vSI crusher? Choosing right hammer is the key Read More »