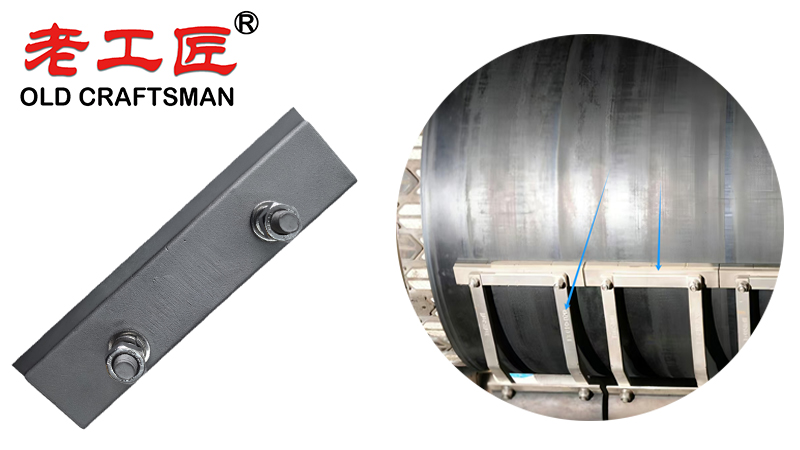

Different Raw Material Used in Mining Conveyor Secondary Belt Cleaner

Old Craftsman with over 12 years of experience in tungsten carbide industry, and use our tungsten carbide wear parts could make your machine use life longer than before!

Different Raw Material Used in Mining Conveyor Secondary Belt Cleaner Read More »