I. Introduction to carbide brazed tips

Brazed tips, which are also referred to as tungsten carbide brazed tips, are minute work pieces comprised of tungsten carbide and metallic binder. These tips have extensive employment in many industrial utilities which demand high durability and resistance to wear.

The formation of brazed tips involves the brazing of a small piece of tungsten carbide to a steel substrate, giving rise to a cutting apparatus that fuses the hardness and resistance to wear of tungsten carbide with the toughness and flexibility of steel. This makes brazed tips an unparalleled choice for circumstances that require the cutting, drilling, or milling of durable materials such as cast iron, steel, and non-ferrous metals.

The compact size of brazed tips facilitates their integration into a wide array of cutting tools, comprising but not limited to saw blades, drill bits, and milling cutters. This versatility endows brazed tips with indispensability as a component of numerous manufacturing and machining processes.

On the whole, brazed tips are imperative in the realm of industrial manufacturing owing to their incomparable blend of toughness, resistance to wear, and versatility. They provide an exceedingly effective solution for the cutting and drilling of formidable materials, promoting the efficient production of top-tier products.

II. Grades of the brazed tips

| Grade | ISO Code | Density | Hardness | T.R.S | Applications recommended |

| g/cm3 | HRA | MPa | |||

| YG3 | K05 | 15.1 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YG6X | K10 | 14.95 | 91.5 | 1800 | The semi-finishing & finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YG6 | K15 | 14.95 | 90.5 | 1900 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG8 | K20 | 14.8 | 89.5 | 2200 | |

| YW1 | M10 | 13.1 | 91.6 | 1600 | Suitable for the semi-finishing and finishing of stainless steel and conventional alloy steel. |

| YW2 | M20 | 13 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 11.4 | 91.5 | 1600 | Suitable for the semi-finishing and finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 11.6 | 90.8 | 1700 | Suitable for the semi-finishing and finishing of steel and cast steel. |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Suitable for the machining of heavy cutting to steel and cast steel, which can be operated with a big feed rate at a medium and low speed under unfavorable working conditions. |

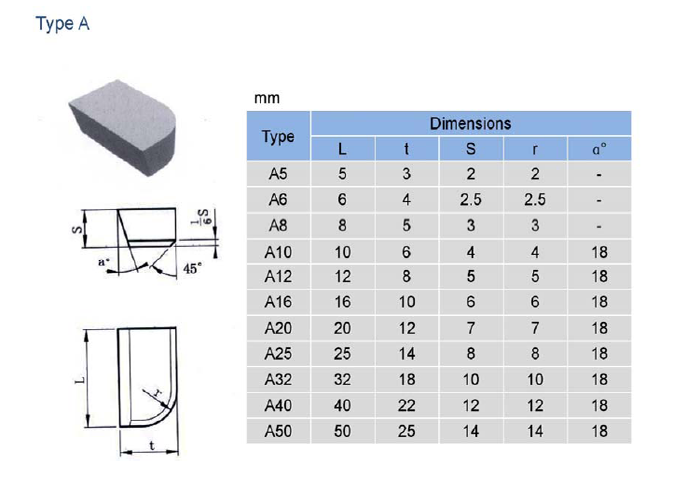

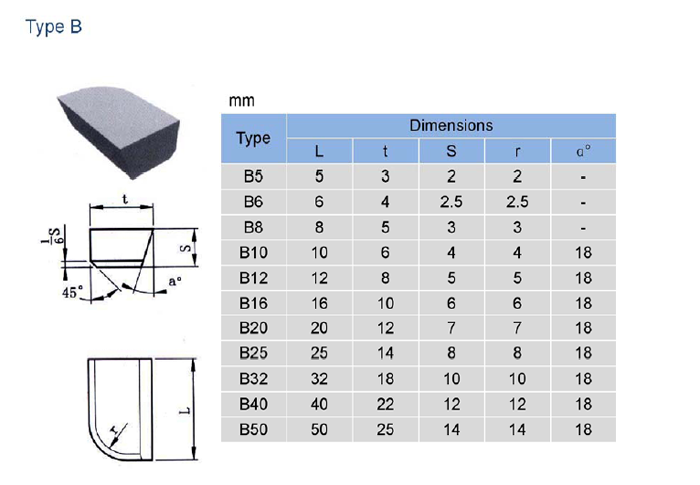

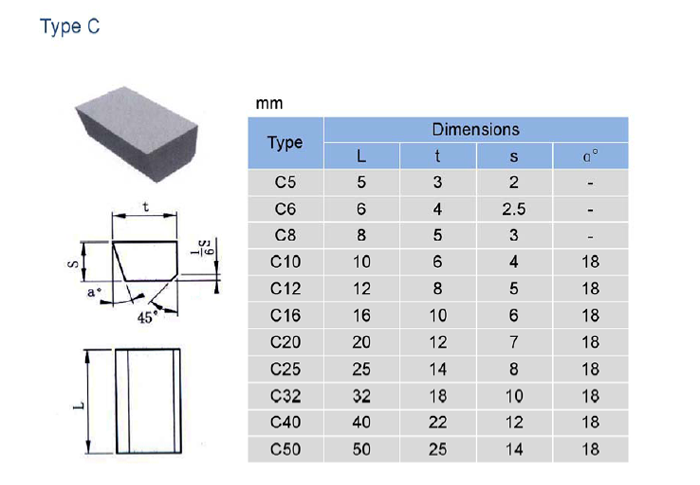

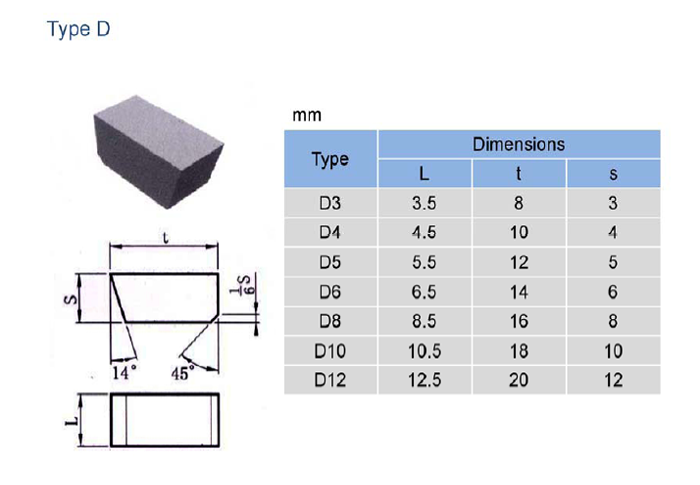

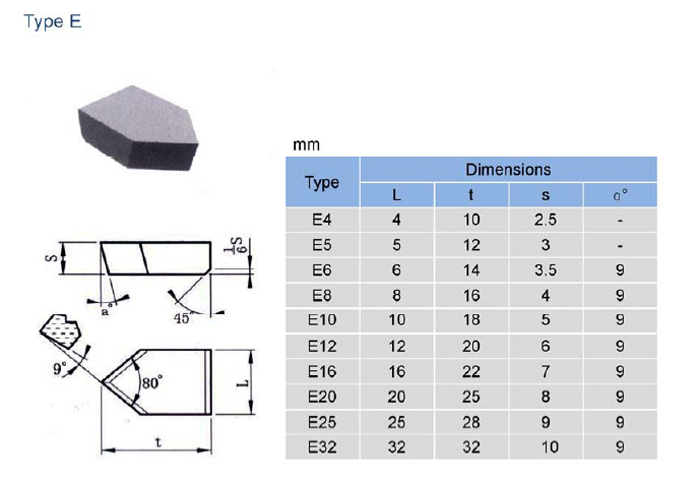

III.Size information for brazed tips

IV. Advantages of zz old craftsman Brazed Tips

- Products have a high hardness and toughness, strong impact resistance, and are difficult to wear during machining, thus avoiding the risk of chipping tools.

- Our brazed tips boast reliable quality as they are inspected rigorously. Moreover, if asked, we can provide detailed reports of test results related to products.

- They come in a variety of grades and models, and could be customized if requested by the customer.

- We integrated researching, designing, production and sales process to a whole, which allows us to eliminate intermediaries, thus providing customers with the most ideal prices.

V. FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.