I.Introduction to carbide shims

Carbide shims utilized in tool holders are small pieces serving to fine-tune the position and height of the tool holder’s cutting edge. The term “shim” denotes a slender piece of material exploited for filling in small crevices or gaps. Usually, carbide shims are composed of composite materials, namely tungsten carbide and metallic binder, yielding remarkable durability and resistance to wear.

The height and position of the cutting edge in tool holders are crucial factors determining the accuracy and efficiency of the machining process. Carbide shims afford a meticulous and stable method for modifying the cutting edge, enabling operators to optimize the tool’s performance according to the specific application.

Further, carbide shims customized for tool holders can be tailored to match the prerequisites of the application. They can be fabricated in varied dimensions and thicknesses, and their constitution can be adjusted to deliver the desired level of toughness and resistance to wear.

The main usage for the Carbide shims is assisting the cutting of carbide inserts, so it has high requirement of the flatness. We need to ensure there is no any gap between two pieces of carbide shims when put together.

The sizes we are mainly producing are American standard. We have almost all the sizes in stock, and can provide you immediate delivery. All the carbide shims are produced with 100% virgin material and through HIP sintering. We are supplying them to branded inserts manufacturers. Because of the high quality control standard, complaint to our products has never shown itself as of today.

II.Grade information of carbide shims

| GRADE | ISO CODE | DENSITY | HARDNESS | Bending Strength |

| g/cm3 | HRA | MPa | ||

| YG8 | K20 | 14.65-14.85 | 90 | 2600 |

| YT5 | P30 | 13.05 | 90.5 | 2200 |

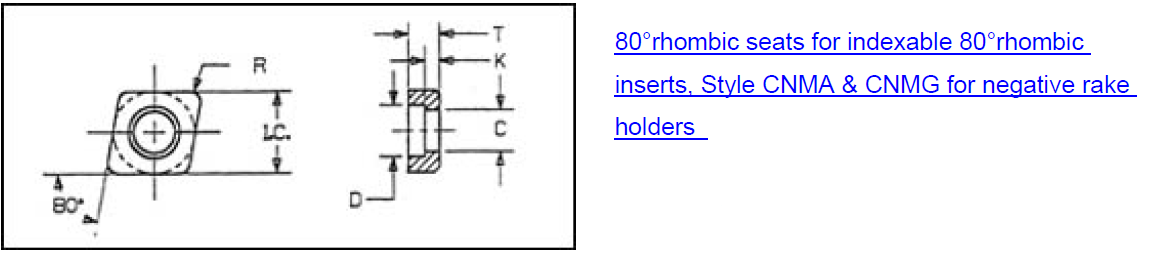

III. Size information of carbide shims

IV.Advantages of zz old craftsman Carbide Shims

- We have various grades and models about the product, and if requested by the customer, customized service is permitted.

- Our company possesses complete and mature production line, and we boast high efficiency in production, thus shortening the time to delivery.

- The carbide shims are superior in hardness and toughness, strong impact resistance, and multi-layers of controlling to products are necessary to ensure the stable quality and win customers’ trust.

- With experienced engineer in the fields of alloy for years, we are able to research and develop special products based on the requirements of onsite usage.

V.FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineer have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.