I. Introduction to Carbide Washer

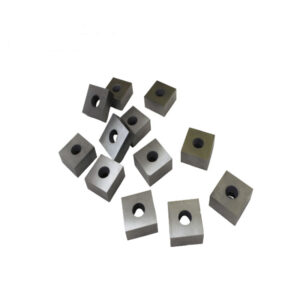

Tungsten carbide washers, circular constituents that display high resistance to wear, hardness, deformation, and corrosion, are deployed in mechanical applications that necessitate these attributes. The washers are comprised of a composite amalgamation of tungsten carbide particles and a metallic binder.

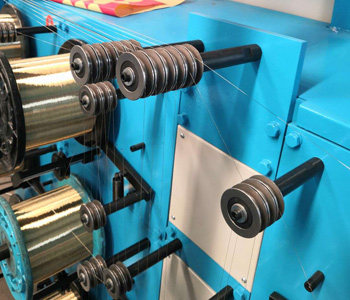

These washers frequently serve as sealing rings in diverse equipment such as valves, pumps, and other mechanical equipment that mandates an airtight seal to prevent any fluid seepage. The utilization of tungsten carbide for sealing applications arises from its exceptional resistance to wear and corrosion, making it an excellent candidate for components that are frequently exposed to abrasive media and demanding operating conditions. Moreover, these tungsten carbide washers come in diverse shapes, sizes, and configurations, tailored to meet the specific needs of various mechanical applications.

II. Grades of the carbide washer

| Grade | Density | T.R.S MPa | Hardness HRA | Performance & application recommended |

| YG6A | 14.95 | 1800 | 92.5 | Fine-grained alloy, great wear resistance. Semi-finishing and finishing of chilled cast iron, non-ferrous metals alloys, hardened steel, alloy steel. |

| YG8 | 14.8 | 2200 | 89.5 | High strength in use, higher impact resistance than YG6, but comparably lower wear resistance and cutting speed. Applied in the roughing of cast irons, non-ferrous metals and their alloys as well as nonmetallic materials at low cutting speed. |

| YG10X | 14.5 | 2400 | 91.5 | Fine-grained alloy, good wear resistance. Used for processing hard wood, veneer board, PCB, PVC and metals. |

| YL10.2 | 14.5 | 2400 | 91.8 | Fine grade alloy, with high wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel, etc. |

| G20 | 14.3 | 2420 | 90.0 | Conventional wear resistance, high bending strength, used for steel alloy etc. |

| YN6 | 14.82 | 2150 | 92.0 | Mainly used for seal ring for oil field and corrosive area |

| YN8 | 14.80 | 2200 | 91.5 | Mainly used for seal ring for oil field and corrosive area |

| YN10 | 14.60 | 2350 | 90.5 | Mainly used for seal ring for oil field and corrosive area |

III.Size information for Carbide washer

| Outside Diameter(mm)

(+0.4/+2.0) |

Inside Diameter(mm)

(-3.0/-0.5) |

Height(mm)

(+0.5/1) |

| φ75 | φ2-50 | 30 |

| φ80 | φ2-55 | 35 |

| φ90 | φ2-60 | 35 |

| φ100 | φ2-65 | 35 |

| φ110 | φ2-75 | 40 |

| φ120 | φ2-75 | 40 |

| φ130 | φ2-80 | 40 |

| φ140 | φ2-80 | 40 |

| φ150 | φ2-100 | 40 |

| φ160 | φ2-100 | 40 |

| φ170 | φ2-100 | 40 |

IV. Advantages of ZZ OLD CRAFTSMAN-carbide washer:

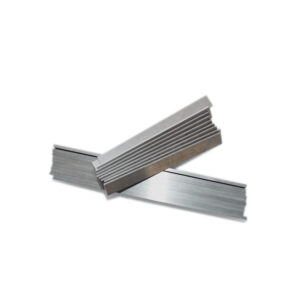

– Grinding after sintering, dimensions and tolerances are controlled strictly, superior sealing performance.

– Rare elements of corrosion resistance is added into the process recipe, more durable sealing performance.

– Use branded tungsten carbide material, no distortion or deformation.

V. Applications of carbide washer

Carbide washers are an invaluable tool for protecting precision machinery in a wide range of industrial contexts. Their ability to resist abrasion, corrosion and heat make them ideal for use in challenging environments such as mining, oil & gas production, automotive manufacturing and aerospace engineering. From acting as durable spacers or shims to providing wear protection on vital moving parts – they can be the difference between costly repairs or smooth operation!

Carbide washers offer essential precision and reliability in a wide range of industrial applications, where their durability helps to improve the efficiency, safety and effectiveness of various systems. From ensuring tight tolerances during electronic component manufacturing to enabling smoother operation for machinery components; carbide washers are an invaluable asset across many industries.

VI.FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.