I. Introduction of Crusher Blade

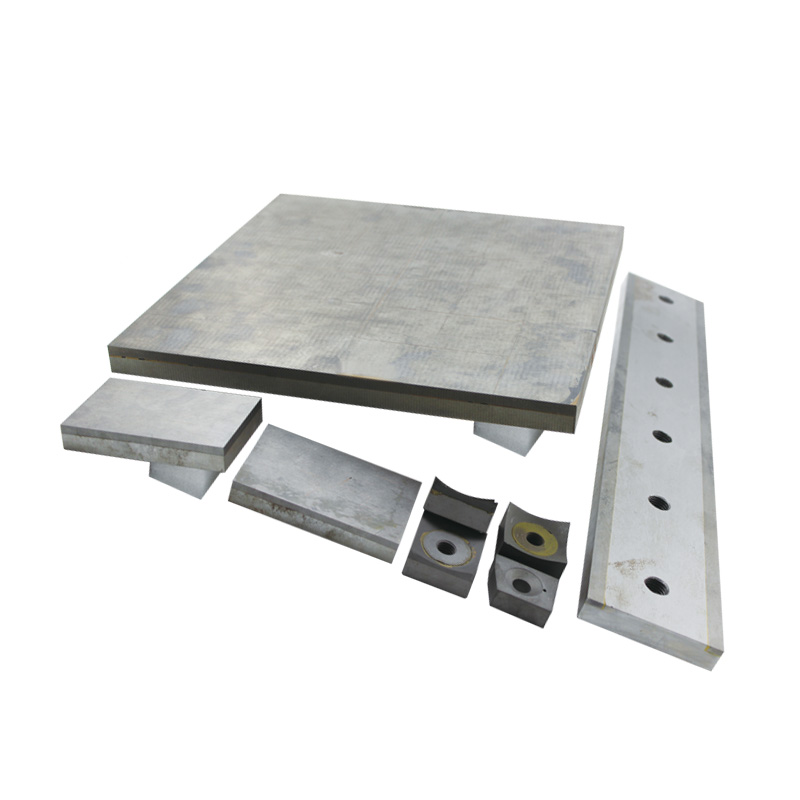

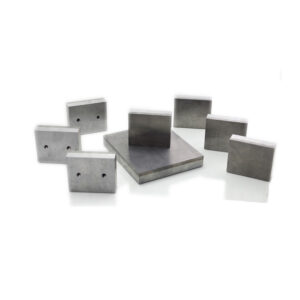

The crusher blade zhuzhou old craftsman precision alloy co ltd produced is brazed by vacuum brazing. After eight years research and development, and cooperating with customer closely on the performance, we finally have matured technique on the brazing. All the brazed products, such as carbide brazed wear plate, carbide brazed conveyor scraper, carbide hammer crusher, carbide brazed cutting blade and so on are satisfied by our customers.

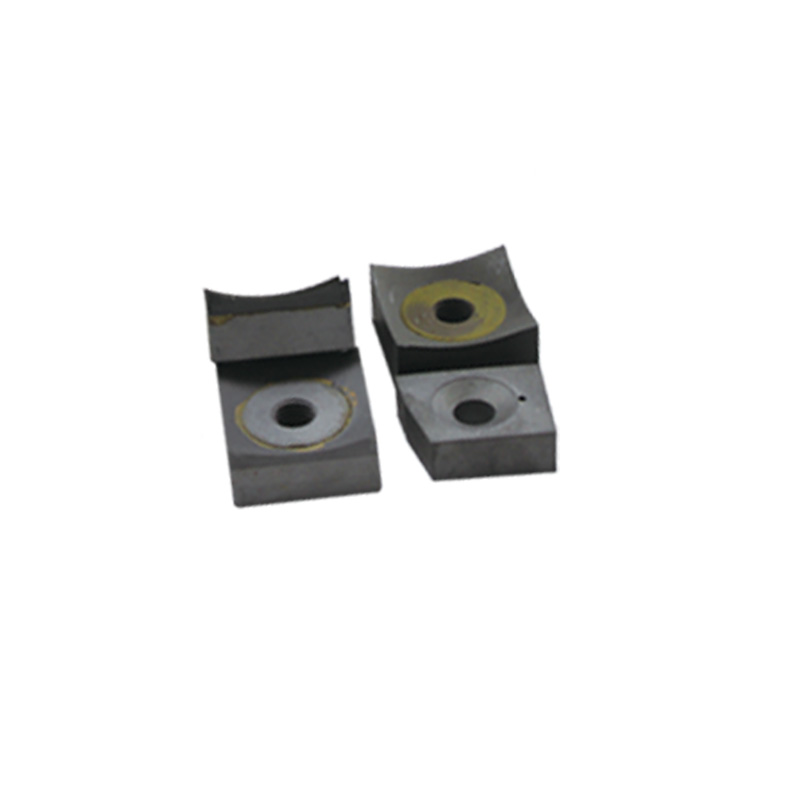

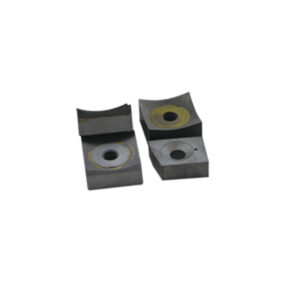

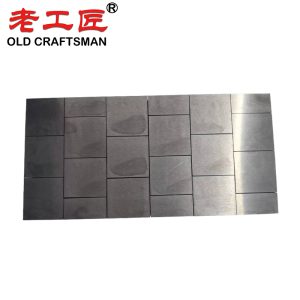

The Crusher blade in the picture is used for crushing and recycling scrap copper, we choose high impact carbide grade for the carbide part. And this kind of products also can be used for crushing other materials. With different carbide grades, the usage is changeable. For examples, we can choose the high wear carbide grade for crusher blade to the sand-making machines. Higher Co percentage grade carbide brazed crusher blades for breaking different composition stones.

II.Production Advantages of Crusher Blade

1. Exact size control, reducing the time and cost of after-grinding and machining.

2. Carbide grade is chosen according to customer detailed requirement on the detailed usage and working environment

3. Using our company researched and developed vacuum brazing technology, guarantying the high brazing strength, no risk of damaging crusher by the falling off carbide.

4. Full set of testing equipment controls the quality on each process, and final inspection before shipment to make sure 100% qualification.

III.Production Advantages of Crusher Blade

1. Exact size control, reducing the time and cost of after-grinding and machining.

2. Carbide grade is chosen according to customer detailed requirement on the detailed usage and working environment.

3. Using our company researched and developed vacuum brazing technology, guarantying the high brazing strength, no risk of damaging crusher by the falling off carbide.

4. Full set of testing equipment controls the quality on each process, and final inspection before shipment to make sure 100% qualification.

IV.FAQ

Q: What kind of brazing you can do?

A: We can do vacuum brazing and high frequency welding, but mainly vacuum brazing, because the brazing quality is much better than other brazing method.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed uage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.

Q: If we want to use carbide brazed product to instead our present ceramic or chrome carbide products, will you support us on the sample testing?

A: Yes, of course. The longest testing we had done with a customer is 8 years. We have enough patience and teamwork to support the sample testing. Our aim is to make high-quality, high cost-effective products, and satisfactory service to satisfy our customers.