I.Product features of secondary belt cleaners

1. Higher Cleaning Efficiency

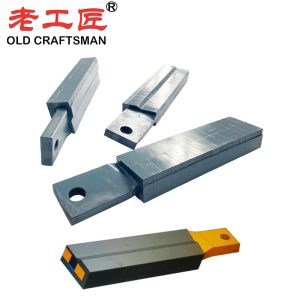

Obviously, the Carbide Conveyor Belt Scraper features lower lifetime cost, because of the carbide durability. Brazing makes the carbide strips more compatible with mechanically-spliced belts as well. That is to say, high bonding strength, high wear resistance, and strong durability.

2. More Cost-effective

Made from pure raw materials and HIP sintering, these cleaners are not only stable and durable but also cost-effective. We use vacuum brazing to ensure high welding strength and low internal stress, and our experienced engineers and technicians can customize the product to meet your specific needs. solution for removing material buildup and preventing belt mistracking.

Considering lifetime cost, higher though the initial cost is, the Carbide conveyor belt scraper can make up the cost difference for its greater durability and fewer regular maintenance, which becomes more important when you think about overall costs.

II. Advantages of zz old craftsman secondary belt cleaners

- Can be applied in the toughest working environment, and higher cleaning efficiency is a key attribute.

- Can be used for highly abrasive materials, and its extreme wear-resistance is the key point.

- Can reduce maintenance times, lessen unacceptable wear rates, and highly improve working efficienecy.

III. Production process of secondary belt cleaners

- Carbide production: Use Chinese best 100% virgin material to guarantee the high wear resistance, TPA presser & HIP sintering to ensure stable quality.

- Use special brazing method for the high bonding strength to avoid carbide blade dislodging.

- Using CNC machining center and grinder for the post-processing, ensuring the precision size.

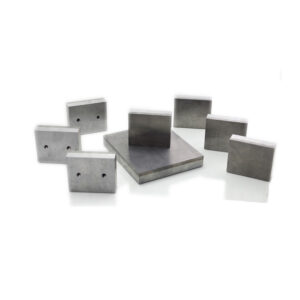

IV. Different sizes of secondary belt cleaners

*Lots of other sizes are under production. Customized sizes are accepted.

We supply such as:

- Secondary belt scraper

- Secondary belt cleaners

- Secondary cleaners

- Belt cleaners

- Belt conveyor scraper

- Belt cleaner conveyor

- Belt conveyor cleaning

- Belt scrapers

- Belt scraper blades

- Conveyor belt scrapers

- Conveyor belt cleaner

- Conveyor belt cleaning

- Conveyor belt scarper blades

- Conveyor scraper

- Conveyor belt wiper

- Mining belt cleaner

- Mining conveyor cleaner

- Quarry belt cleaner

- Aggregate conveyor cleaner

- Heavy-duty secondary cleaner

V.FAQ about Carbide Conveyor Belt Cleaner/Scraper:

1.Q: Can you customize the products according to samples or drawing design?

A: Yes. We have professional engineers to support the customized products for our customers.

2.Q: Can you put our company’s logo on the products?

A:Yes. we can put your logo if you can provide us with the copyright and letter of authority.

3.Q: What kind of payment do you accept? Can I pay RMB?

A: We accept T/T(Wire transfer), Western Union, and Paypal. And we can also accept RMB.

4.Q : What about your delivery time?

A: Delivery time for Carbide Conveyor Belt Scraper is about 20-40 days, depending on the order quantity.