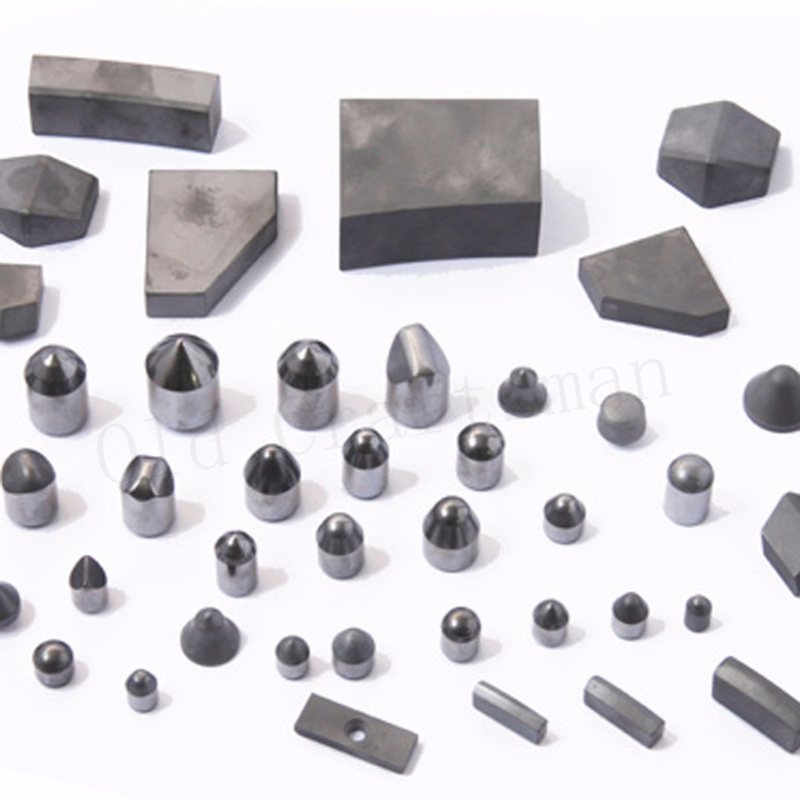

I. Introduction to tungsten carbide button

Tungsten carbide buttons, which are cylindrical components of small size, are extensively used in the mining, construction, and oil drilling sectors due to their exceptional durability and wear-resistance. These buttons are generally employed as cutting elements on drill bits, also known as carbide button bits, and are used in various drilling applications, including the penetration of rock, soil, and other tough materials. The buttons made of tungsten carbide offer superior hardness and wear resistance to the bit, whereas the metallic binder assists in holding the buttons together and maintaining their structural integrity.

The importance of tungsten carbide buttons and carbide button bits in the mining, construction, and oil drilling industries cannot be overstated, for several reasons.

To begin with, these sectors frequently involve drilling through hard and abrasive materials like rock and soil, which can shortly deteriorate conventional drill bits. Tungsten carbide buttons provide superior wear resistance and hardness to the drill bits, making them highly effective in such harsh operating conditions.

Secondly, tungsten carbide buttons exhibit remarkable toughness, allowing them to endure high levels of impact and shock during drilling operations. This makes them highly dependable and long-lasting, reducing the need for frequent bit replacements and increasing productivity.

Lastly, tungsten carbide buttons are highly resistant to corrosion and chemical degradation, which ensures the longevity and reliability of the drill bits in harsh and corrosive environments.

II. Grades of the tungsten carbide button

| Grade | Density | TRS | Hardness | Performance & application recommended |

| g/cm3 | MPa | HRA | ||

| YG4C | 15.1 | 1800 | 90 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

| YG6 | 14.95 | 1900 | 90.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in the fields of geological prospecting, coal mining and oil well boring. |

| YG8 | 14.8 | 2200 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining, oil-well boring and snow clearing. |

| YK05 | 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

| YG8C | 14.8 | 2400 | 88.5 | |

| YK15 | 14.6 | 2450 | 87.6 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospection buttons, cut soft and medium hard formations. |

| YK20 | 14.4 | 2500 | 86.8 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

| YK25 | 14.4 | 2550 | 87.2 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations. |

| YG11C | 14.4 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

| YG13C | 14.2 | 2850 | 86 | Primarily for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and very hard formations. |

| YG15C | 14 | 3000 | 85.5 | For oil cone drill bits, for medium soft and medium-hard rocks. |

*Can adjust the grade according to client onsite using requirement.

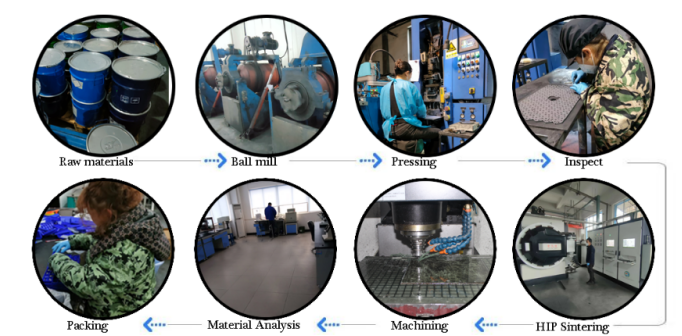

III. Production process of tungsten carbide button

IV. Advantages of zz old craftsman Tungsten Carbide Button

- Our company is able to produce any sizes or styles available on customer’s requests, with high quality as a guarantee.

- Products’ quality can be checked and traced through every process, and it is available to provide relevant testing reports.

- With integrated mature process including production, researching, designing and sales process, our company aims to eliminate intermediaries, thus providing customers with the most ideal prices.

V.FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.