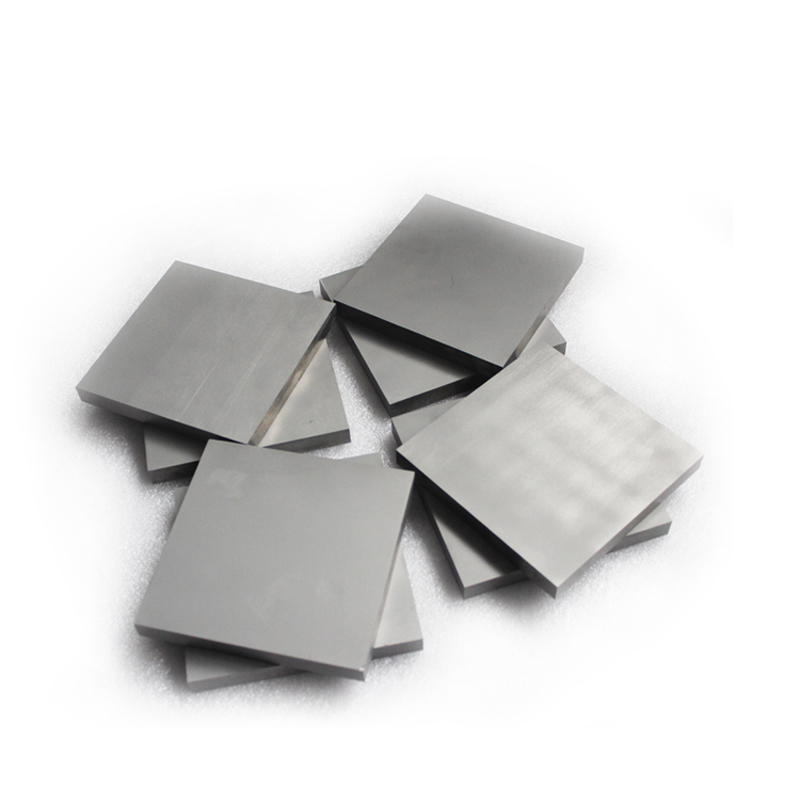

I. Introduction to Tungsten Carbide Plate

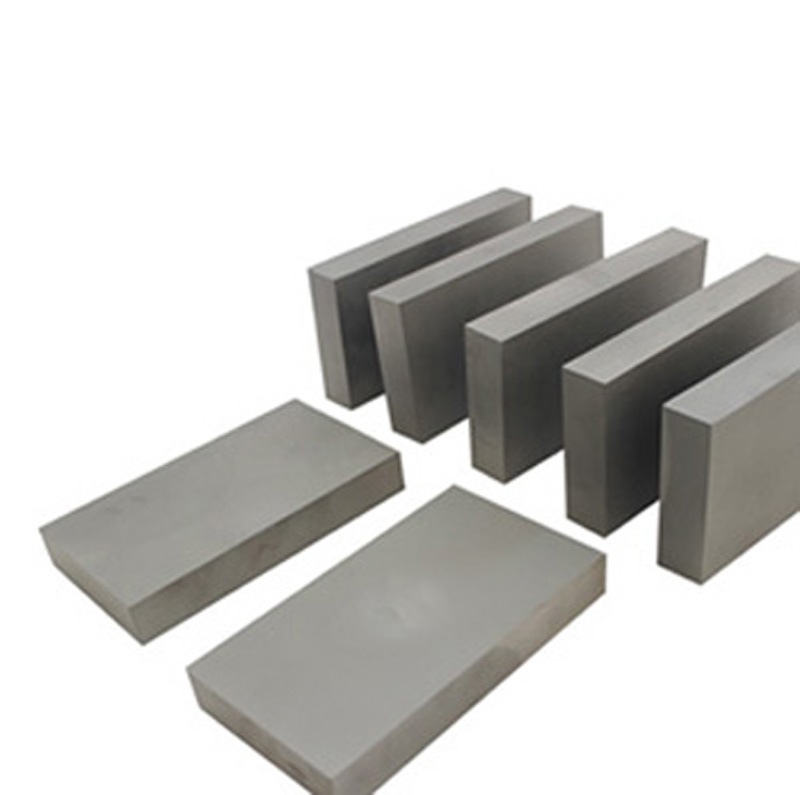

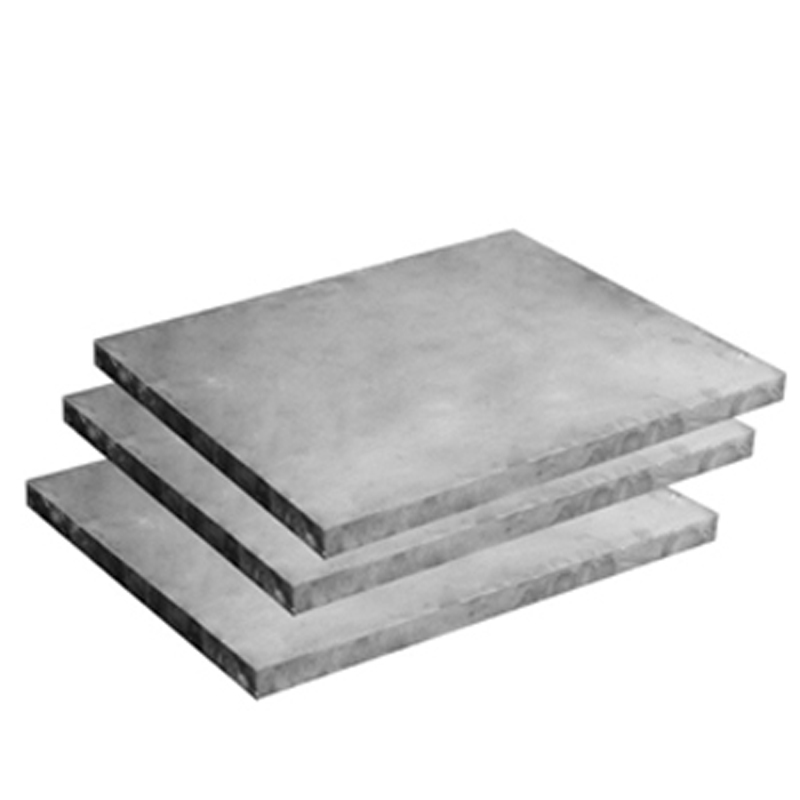

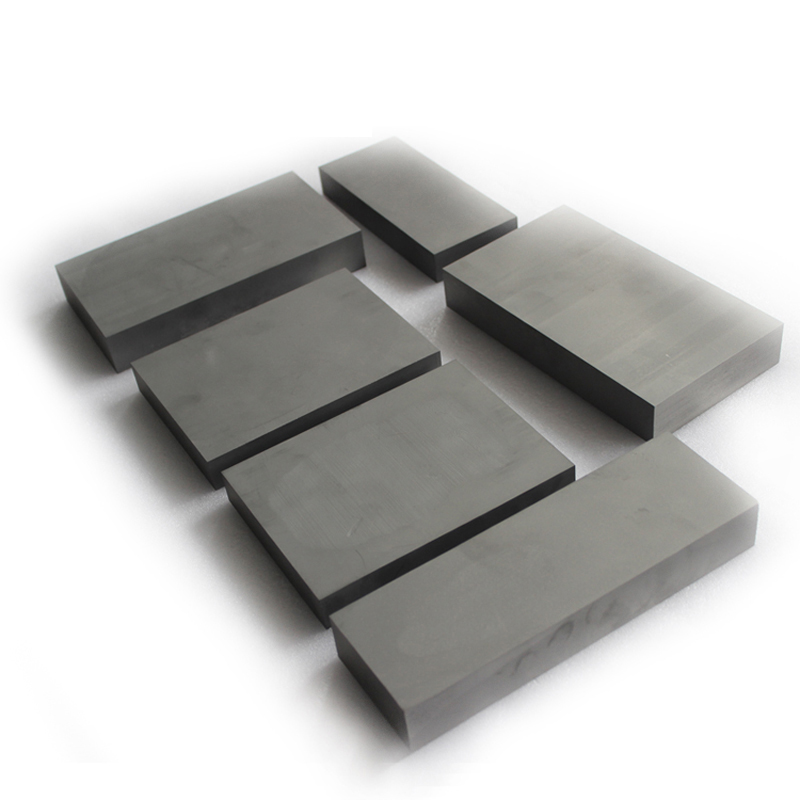

Carbide plates, referred to as tungsten carbide plates, or cemented carbide plates represent planar components of composite materials derived from tungsten carbide and metallic binder. These plates are extensively utilized in multiple industrial applications which require elevated durability and tenacity.

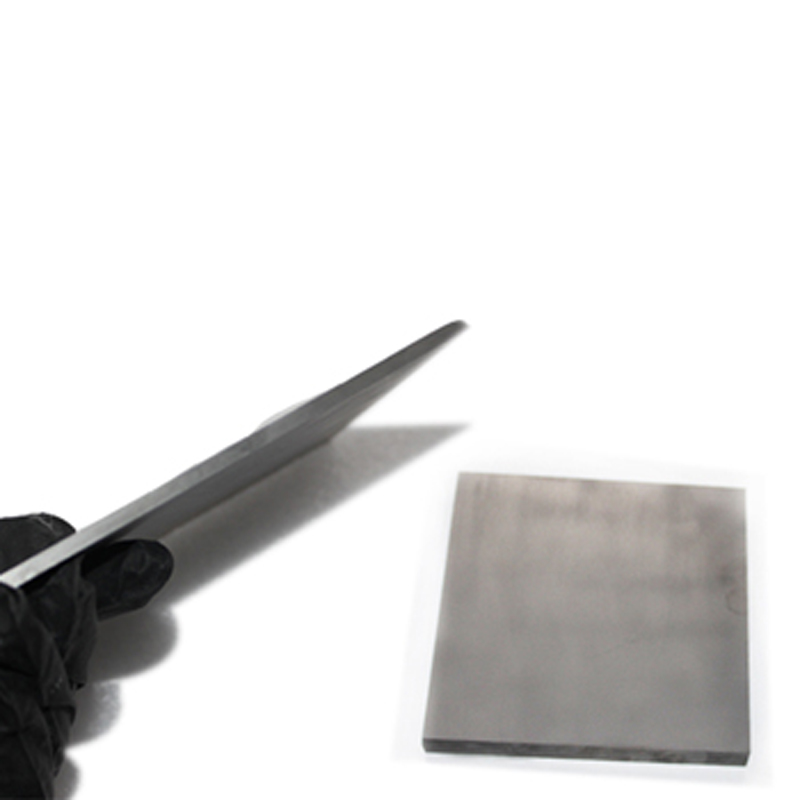

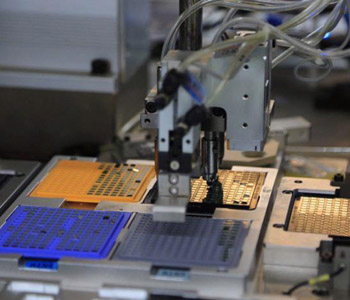

The manufacturing of cutting tools such as milling cutters, saw blades, and drill bits, as well as the production of wear components like valves, nozzles, and seals, frequently incorporate carbide plates. The particles of tungsten carbide contained in these plates facilitate unparalleled hardness and wear resistance, while the metallic binder consolidates these particles to sustain their structural integrity.

Carbide plates are available in a numerous of dimensions and thicknesses to cater to diverse industrial applications. Our company offers a vast spectrum of carbide plates which are meticulously customized to meet the distinctive requirements of our clients.

II.Grade for Tungsten Carbide Plate

| GRADE | ISO CODE | COBALT CONTENT | DENSITY | HARDNESS |

| (%) | g/cm3 | HRA | ||

| K10T | K05-K10 | 4.5-6.0 | 14.95-15.05 | 92.7 |

| YG8 | K30 | 8 | 14.8 | 89.5 |

| YG6 | K20 | 6 | 14.95 | 90.5 |

| YG6X | K10 | 6 | 14.95 | 91.5 |

| YL10.2 | K30 | 10 | 14.5 | 91.8 |

| YG13X | K30-K40 | 13 | 14.3 | 89.5 |

| YG15 | K40 | 15 | 14 | 87.5 |

*Can adjust the grade according to client onsite using requirement.

III.Tungsten Carbide Plate Size Information

| L(mm) | W(mm) | T(mm) |

| 100 | 100 | From 5 to 30 |

| 105 | 105 | From 5 to 30 |

| 200 | 200 | From 5 to 30 |

| 250 | 250 | From 5 to 30 |

| 300 | 300 | From 5 to 30 |

*Sizes can be customized.

IV.Advantages of old craftsman Tungsten Carbide Plate:

- Branded pure virgin material to control the best quality.

- 500T presser with side pressure, good compactness.

- HIP sintering treatment to released inner stress from top to bottom.

- Great polishing

V.Application of tungsten carbide plate:

VI.FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.