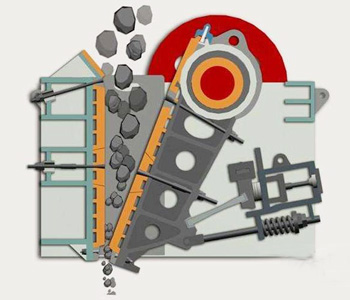

VSI stands for Vertical Shaft Impact, which is a type of crusher used for crushing materials such as rocks, ores, and minerals. The rotor is the main rotating component of the VSI crusher, and the tips of the rotor are the wear parts that come into contact with the material being crushed. The rotor tips are typically made of tungsten carbide, which is a hard and durable material that can withstand the high impact forces and abrasion that occur during the crushing process. The tips can be replaced when they become worn or damaged, which helps to extend the life of the rotor and maintain the crusher’s performance. The design of the rotor tip can also affect the crushing efficiency and the quality of the final product. Different types of rotor tips can be used depending on the application and the type of material being crushed, such as round tips for softer materials and flat tips for harder materials.

I. ZZ CRAFTSMAN customizes to design and produce the unique hammer for each customer:

1. Customize the crusher hammer carbide grade according to the stone size

We use 100% virgin material with HIP for all the tips of the rotor tips and wear plates. We can develop the carbide grades according to the stone sizes, for example for 60-80mm stones, we choose high-impact carbide grades, while for the 10mm stones, we use high-hardness carbide grades. And with our company-branded material of high hardness, we are producing the high hardness and high strength carbide to meet the end-users onsite requirement to length the service life. For bigger sizes, we choose higher impact carbide grade, while higher wear-resistant carbide grade for smaller sizes.

2. Customized design

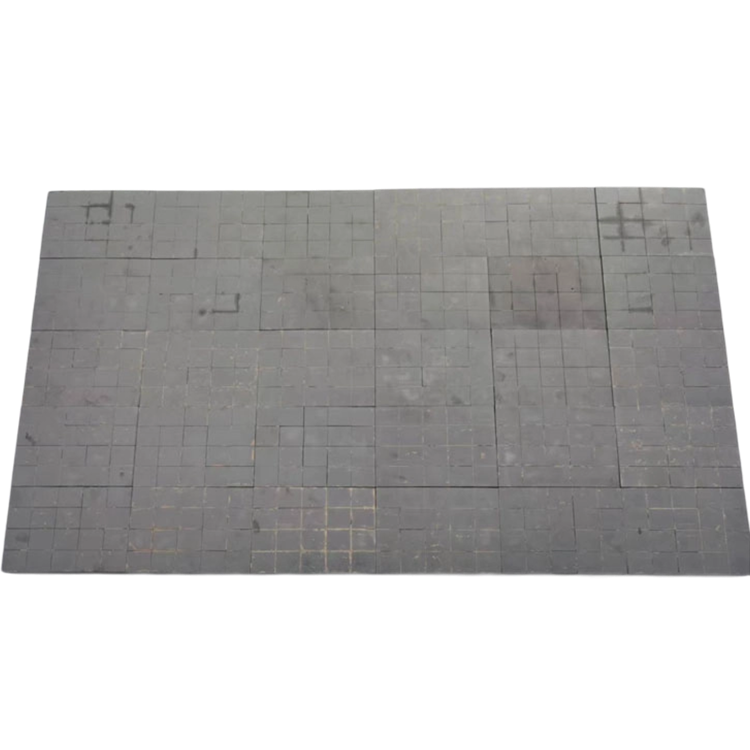

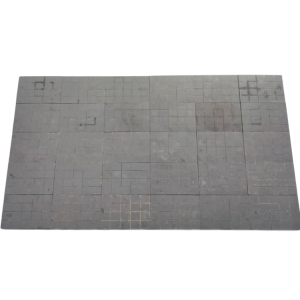

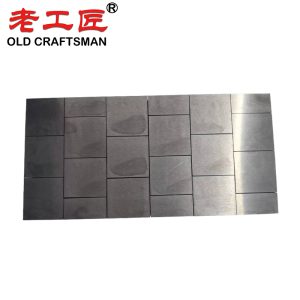

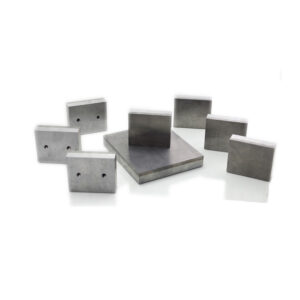

At present, the usual design is carbide strips/carbide bars mounted into the slot of the VSI Rotor Tip. We use a totally different design for this, we suggest protecting the whole wear face. Many customers have doubts at the beginning because more alloys are used, and the cost of the product increases, but count on the service life, you would find out the design is much more cost-effective.

3. Vacuum brazing, small internal stress

The main advantages of vacuum brazing are high bonding strength, tighter tolerances, and high efficiency. Our engineer knows the wide range of filler materials and their standards. Choosing a filler material with high bonding strength is very important, which affects the using life of the rotor tips directly. And how to release internal stress is also very important. With high internal stress, the carbide tips will become very brittle, and the performance of the carbide will become very brittle, and the performance of the carbide will be greatly reduced.

As have experienced knowledge of them, the rotor tips and wear plates our company produced are with high bonding strength and less internal stress.

II. Carbide brazed crusher spare parts advantages:

- customized carbide grade according to onsite usage

- Excellent wear and impact resistance with branded material

- Extended using life

- Varied sizes and types are available

- Customized samples and designs are provided

III. Production process of Crusher Spare Parts:

- Carbide production: Use the Chinese best 100% virgin material to guarantee high wear resistance, TPA presser & HIP sintering to maintain stable quality and quality inspection throughout the whole production process.

- Vacuum brazing to ensure high bonding strength to avoid carbide plate dislodging.

- Special heat treatment to release internal stress.

- Use a CNC machining center and grinder for the post-processing, ensuring the precision size.

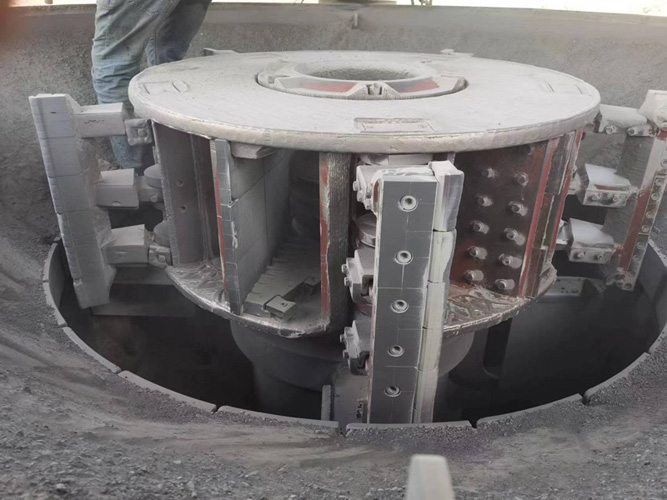

IV. Installation of Crusher Spare parts:

Below are some pictures of how to install our Crusher spare parts, and they are provided by our customers.