Here are the factors that affect the service life of the hammer head in a hammer crusher, explained as below:

★ Material of the Hammer Head: The composition and quality of the material used (e.g., high manganese steel, alloy steel, or wear-resistant composites) determine its resistance to wear and impact. Higher-quality materials generally result in a longer service life.

★ Properties of the Crushed Material: The hardness, abrasiveness, and size of the material being crushed directly impact the hammer head’s lifespan. Harder and more abrasive materials, such as quartz or granite, accelerate wear compared to softer materials like limestone.

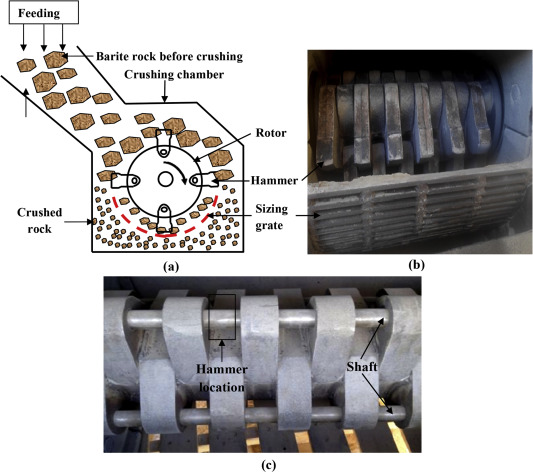

★ Impact Load and Rotor Speed: The intensity of the impact force and the rotational speed of the crusher affect the hammer head’s durability. Excessive speed or heavy loads can cause fatigue, cracking, or accelerated wear.

★ Hammer Head Design: The shape, weight, and balance of the hammer head influence its wear pattern and lifespan. An optimized design ensures even wear and efficient crushing, while a flawed design may lead to premature failure.

★ Operating Environment: Conditions such as moisture content, temperature, and dust levels affect the hammer head. High moisture can cause material buildup, increasing wear, while elevated temperatures may weaken the hammer head’s material strength.

★ Feed Rate and Material Flow: An inconsistent or excessive feed rate can overload the hammer head, leading to uneven stress and faster deterioration. Proper control of material flow helps prolong its life.

★ Maintenance Practices: Regular inspection, timely replacement, and correct installation are crucial. Neglecting maintenance or using worn-out hammers beyond their limit shortens their service life.

★ Manufacturing Process: The quality of production, including casting precision, heat treatment, and surface hardening, affects the hammer head’s ability to withstand wear and impact. Poor manufacturing can result in defects that reduce lifespan.

These factors collectively determine how long the hammer head will last under specific operating conditions. Proper selection and management of these variables can significantly extend its service life.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work