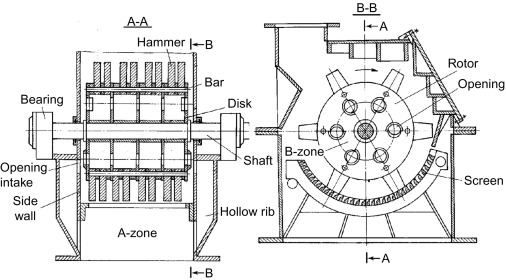

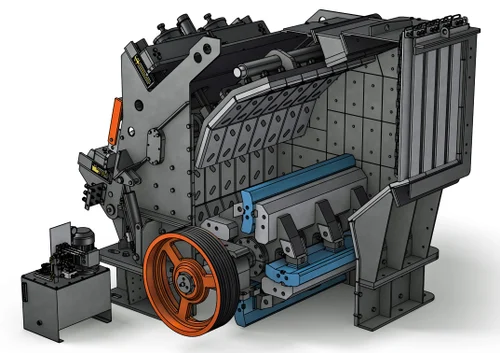

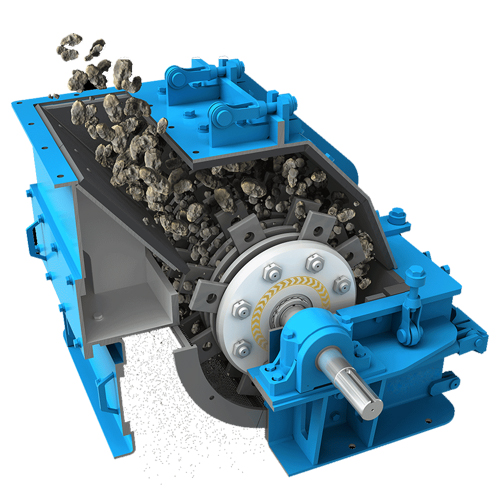

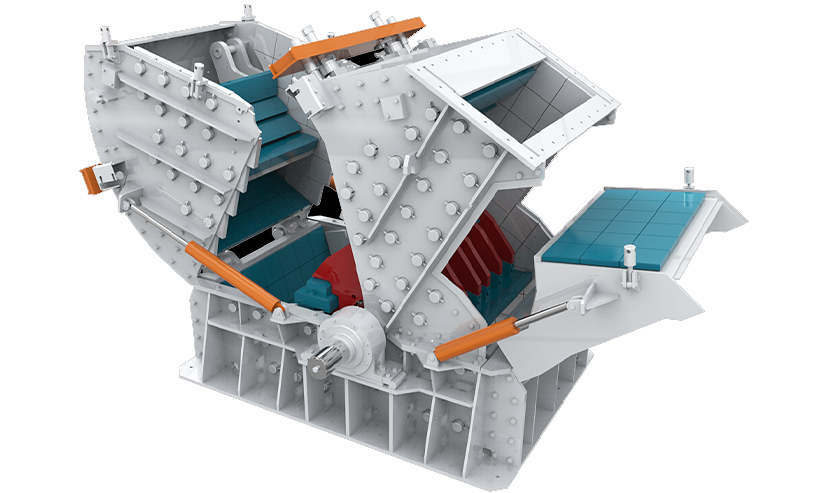

The importance of tungsten carbide crusher hammer in the crushing process lies in its exceptional durability, wear resistance, and ability to maintain efficiency under demanding conditions. Made from hard metal alloys, such as tungsten carbide combined with cobalt or other binders, carbide hammerheads offer unique advantages that significantly enhance the crushing operation. Here’s why they are critical:

1.Superior Wear Resistance: Hard materials like rocks, ores, or concrete are highly abrasive. Carbide hammerheads resist wear and deformation far better than traditional materials like high-manganese steel, extending their operational lifespan and reducing downtime for replacements.

2.High Impact Strength: The crushing process involves repeated high-force impacts. Carbide’s toughness allows the hammerhead to withstand these forces without cracking or breaking, ensuring consistent performance when breaking down hard and brittle materials.

3.Improved Crushing Efficiency: The hardness of carbide enables the hammerhead to maintain its shape and sharp edges longer, delivering more effective and precise impacts. This results in faster material breakdown and a more uniform output size, enhancing overall productivity.

4.Cost-Effectiveness Over Time: Although carbide hammerheads may have a higher initial cost, their longevity and reduced maintenance needs lower the total operational cost, making them a valuable investment for industries like mining, quarrying, and cement production.

5.Versatility: Carbide hammerheads perform exceptionally well across a wide range of materials, from soft limestone to tough granite, making them adaptable to various crushing applications.

In summary, the carbide crusher hammerhead is vital for ensuring durability, efficiency, and cost-effectiveness in the crushing process, particularly when handling challenging materials. Its ability to endure harsh conditions while maintaining performance makes it indispensable in heavy-duty industrial settings.

Zhuzhou Old Craftsman Precision Alloy Co., Ltd. produce carbide vacuum brazed wear parts, like wear liners, hammers and wear spare parts for crushers, mixing blades, conveyor belt scrapers, etc. for mining and crushing. The performance is tens of times longer than the present material. These products can help customers save lots of time and money on the shutdown. If you have any wear problems, welcome to contact us for free customized design.

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work