Test Overview

- Product Name: Cemented Carbide Multilayer Composite Vertical Shaft Crusher Hammer

- Test Location: Chaling, Hunan

- Test Duration: November 2024 – January 2025

- Test Equipment: Vertical Hammer Crusher (Diameter: 1.2 meters, Speed: 900 RPM)

- Test Material: Tungsten Ore

The tungsten ore used during the test is shown in the figure below:

Customer Pain Points Analysis

The High Chrome Cr26 hammers currently used by customers are facing the following difficulties:

- Low Efficiency: The crushing efficiency significantly decreases as the hammer wears out, impacting overall production capacity.

- Short Lifespan: The single-sided usage time is only 16-20 hours, and frequent replacements negatively affect production efficiency.

- Cumbersome Replacement: Each hammer weighs 28.7 kilograms, making replacement time-consuming and labor-intensive, especially in harsh working environments.

The following are the scrapped high chrome hammers:

Innovative Solutions

We deeply understand the problems of customers and have developed a new carbide multi-layer composite hammer head:

- Multi-layer carbide design: Each layer of carbide grade has its own unique function, with super impact resistance and wear resistance.

- Brazing: The unique brazing process ensures the perfect fusion of multiple layers of materials, and the brazing surface is strong and durable.

- Customized structural optimization: Designed specifically for high-speed equipment, it improves the overall performance of the hammer head and adapts to extreme working conditions. We adopt a customized solution designed for each customer to help customers solve problems according to actual conditions.

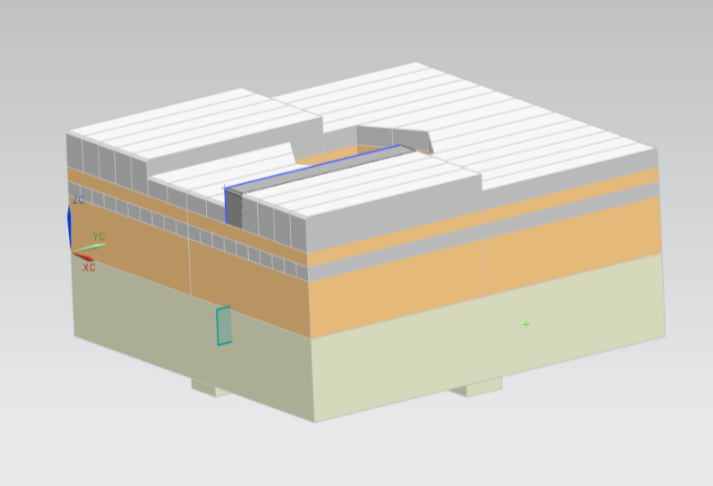

The following are pictures of the vertical hammer crushing equipment used for testing:

The left is a photo of the Cr26 hammer that needs to be replaced;

The right is the status of the carbide hammer after 150 hours of work

The following are the design and product pictures of the cemented carbide multi-layer composite hammers.

Experimental comparison data

| Performance Indicators | Cr26 Hammer | Tungsten Carbide hammer |

| Single-side use time (hours) | 16-20 | >240 |

| Service life | 32-40 hours | >480 hours |

| Wear rate | Efficiency drops significantly after 10 hours of wear | Wear is significantly reduced, maintaining efficient operation of equipment for a long time |

| Replacement frequency | Frequently | Extremely low |

Test Results

The performance of our tungsten carbide hammer under actual working conditions:

- Eco-Friendly: Reduces the recycling and disposal of discarded high-chromium hammers, conserving resources and promoting environmental sustainability.

- Durability: After 150 hours of continuous operation, the equipment maintained efficient output, whereas the traditional Cr26 hammer required replacement three times.

- 15x Longer Lifespan: Testing shows that production lines using our full tungsten carbide hammer experience significantly fewer replacements, substantially reducing downtime.

- Enhanced Production Efficiency: Wear is significantly reduced, and crushing performance remains stable, leading to a noticeable improvement in overall productivity.

Company advantages

- Cemented carbide R&D and production: We have a complete cemented carbide R&D and production line, and control the quality from the powder.

- Welding: After 12 years of research and development, we have our own unique welding process and customized fully automatic welding equipment.

- Customer-centric: We develop customized solutions one-to-one according to customer needs.

Through this experiment, we can know that the cemented carbide vacuum brazing hammer customized and produced by our Old Craftsman is significantly superior to the traditional high-chromium hammer in terms of wear resistance, service life and production efficiency. Its higher hardness (HRA 89-91) and unique welding process significantly enhances wear resistance and reduces downtime caused by frequent hammer head replacement.

The carbide vacuum brazing hammer performs well in high impact and high wear environments. Its lifespan and performance are more than 15 times that of the high chromium hammer, which can greatly improve the production efficiency of the equipment while reducing resource waste and environmental burden.

If you are looking for a high wear-resistant crusher hammer, please feel free to contact us.

We will have a professional team to connect with you and tailor a suitable solution for you.