Industries operating in abrasive and corrosive conditions face significant challenges in maintaining the longevity and performance of their equipment. At ZZ Old Craftsman, our tungsten carbide wear plates offer a revolutionary solution, providing exceptional durability and extending the service life of critical components.

Unmatched Wear Resistance for Extreme Applications

Tungsten carbide, renowned for its hardness and resilience, forms the core of our wear plates. Whether it’s handling high-impact materials in crushers or enduring the relentless abrasion in mining hoppers, these plates are engineered to withstand the toughest operational demands. Field tests consistently show that our wear plates last up to three times longer than conventional steel liners, dramatically reducing maintenance frequency and downtime.

Proven Success in Real-World Conditions

Case Study: Extending Hopper Life in Mining Operations

A mining company in Australia faced frequent breakdowns in its material hoppers due to severe wear from hard rock and abrasive ores. After installing our tungsten carbide wear plates, the hopper’s service life more than doubled, cutting repair costs by 40% and increasing operational uptime by 30%.

Enhanced Durability in Cement Plants

In a cement manufacturing plant, our wear plates were applied to raw mill chutes, where material flow caused rapid erosion. The upgraded liners not only improved wear resistance but also contributed to a 20% increase in material handling efficiency.

Key Advantages of Tungsten Carbide Wear Plates

Exceptional Hardness: With a hardness exceeding 88 HRC, our wear plates can resist even the most abrasive materials.

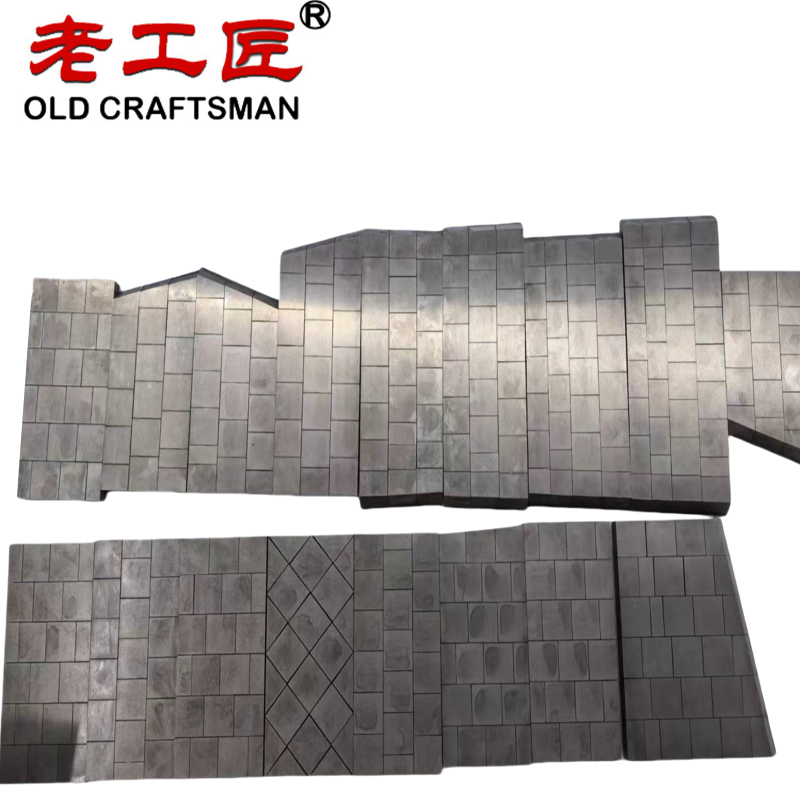

Customizable Solutions: Plates can be tailored in shape, thickness, and mounting style to suit specific operational needs.

Corrosion Resistance: Ideal for environments where chemical exposure accelerates wear.

Reduced Total Cost of Ownership: Fewer replacements and repairs mean long-term savings.

Applications Across Industries

Our tungsten carbide wear plates are transforming operations in diverse sectors:

Mining: Protecting crushers, chutes, and hoppers from abrasive ore.

Construction: Enhancing the durability of excavator buckets and bulldozer blades.

Agriculture: Shielding tillage tools and grain handling equipment from wear.

Steel Mills: Improving the lifespan of material handling components.

What Makes ZZ Old Craftsman the Preferred Choice?

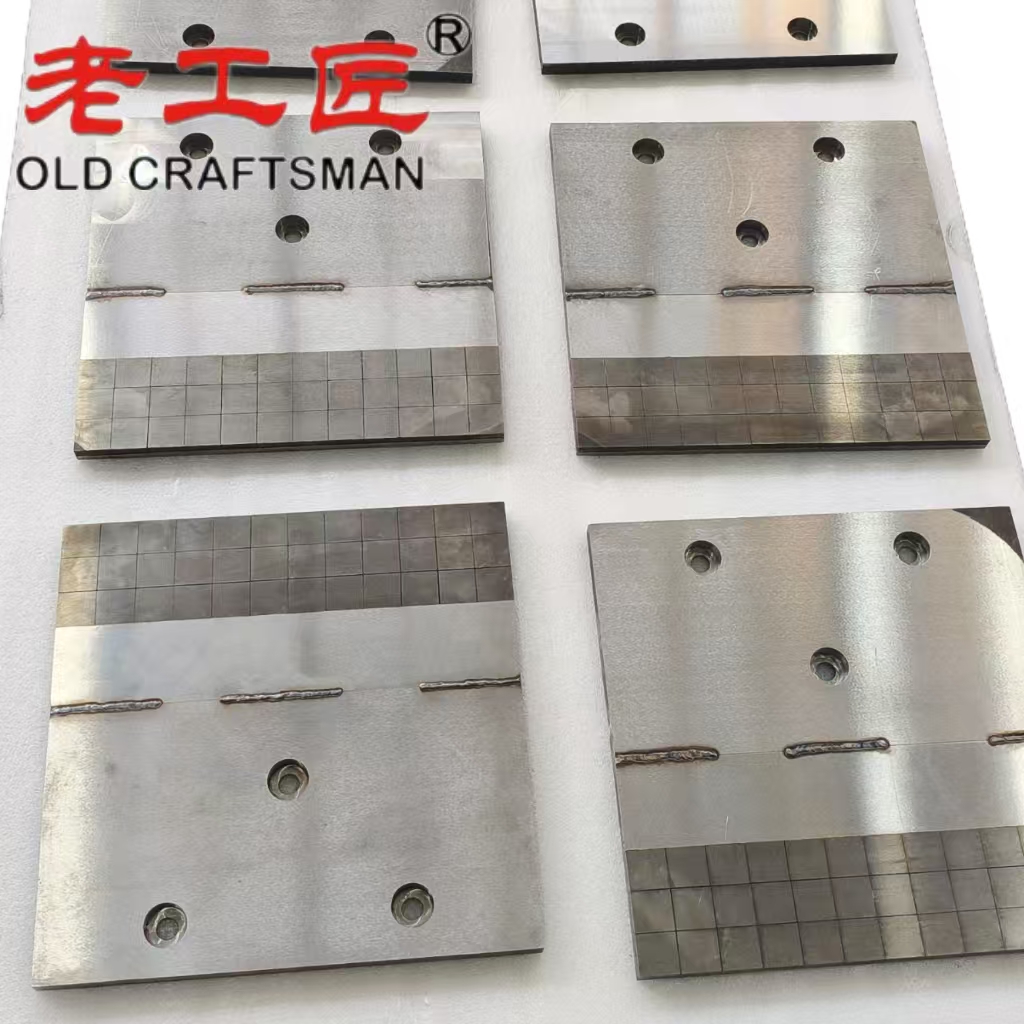

Advanced Manufacturing:

Using vacuum brazing technology, our wear plates achieve a perfect bond between the tungsten carbide and steel backing, ensuring maximum durability.

Expert Support:

From material selection to installation guidance, our team provides end-to-end assistance.

Sustainable Solutions:

By extending equipment lifespan, our wear plates contribute to resource conservation and reduced environmental impact.

Future-Proof Your Equipment

Don’t let wear and tear dictate your downtime. With ZZ Old Craftsman’s tungsten carbide wear plates, you can tackle the harshest conditions with confidence. Contact us today to learn how our solutions can revolutionize your operations.