Where are the impact hammer crushers used with tungsten carbide wear parts?

Parts of a Crusher That Require tungsten Carbide Wear-Resistant Components

Crushers are subjected to intense impact, abrasion, and friction during operation, making hard alloy (such as tungsten carbide or similar materials) wear-resistant components essential in key areas to enhance durability and performance. The specific parts include:

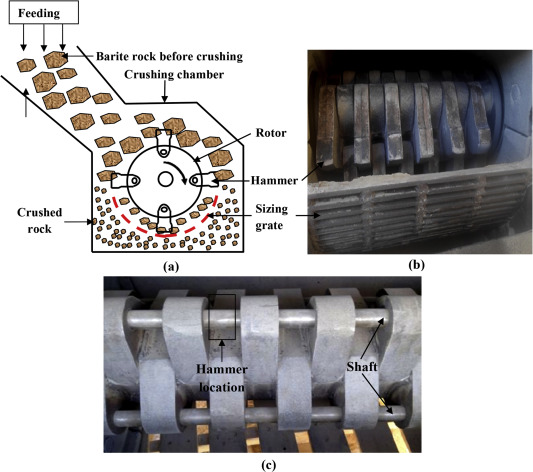

✦ Hammer Heads

- Application: In hammer crushers, the hammer heads are the primary components that directly strike and crush the material.

- Reason: They endure severe impact and abrasive wear from continuous contact with hard materials like rocks or ores. Hard alloy is either embedded into the hammer heads or applied as a surface overlay (e.g., through welding) to reinforce them.

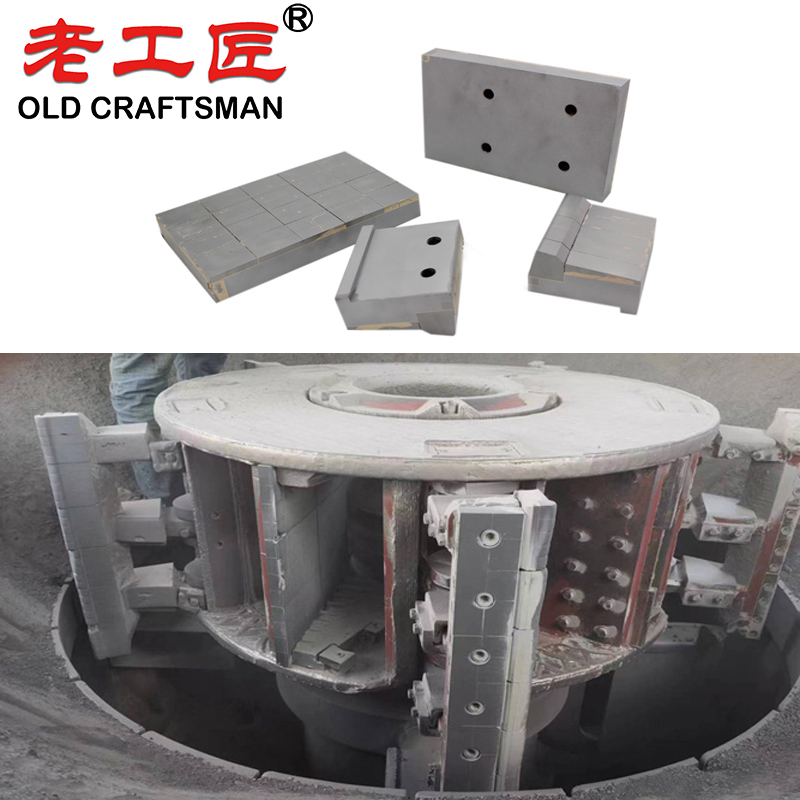

✦ Liners (Wear Plates)

- Application: Liners are used in various crushers, such as the fixed and movable jaw plates in jaw crushers, or the impact plates in impact crushers.

- Reason: These components are exposed to constant friction, squeezing, and grinding from the material being processed. Hard alloy liners or hard alloy overlays protect the crusher’s body and maintain its structural integrity.

✦ Blades or Tooth Plates

- Application: In shear-type or shredder crushers, blades or tooth plates are responsible for cutting or tearing materials apart.

- Reason: These parts require exceptional hardness and wear resistance to handle tough or abrasive materials effectively. Hard alloy ensures the blades remain sharp and durable over time.

✦ Rotor Components

- Application: In high-speed rotating crushers like impact crushers or vertical shaft impact (VSI) crushers, rotor parts such as blow bars, throw heads, or striking plates are critical.

- Reason: The rapid rotation causes intense wear from material impact and abrasion. Hard alloy reinforcements in these areas improve resistance to wear and cracking.

✦ Discharge Area and Screen Plates

- Application: The discharge port and screening components (e.g., sieve plates) at the crusher’s output end.

- Reason: These areas experience frequent material flow and friction, leading to gradual wear. Hard alloy reinforcements reduce erosion and extend the lifespan of these parts.

Conclusion

The use of tungsten carbide wear-resistant components is critical in parts of a crusher that experience direct material contact, high abrasion, or intense mechanical stress. Their application depends on the crusher type (e.g., jaw, hammer, impact) and the material being processed (e.g., hardness, size). The benefits—ranging from increased durability and efficiency to cost savings—make hard alloy an indispensable material in modern crusher design and maintenance.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work