In heavy-duty industrial applications, the battle against wear is a constant one. From the rugged terrain of mining sites to the abrasive environments of mineral processing facilities, machinery faces significant challenges that require rugged solutions. Historically, wear-resistant steel, high-chromium cast iron, and high-aluminum ceramics have been the mainstays of wear protection. While each material has laudable properties, they often perform poorly under extreme conditions. For example, wear-resistant steel, while exhibiting excellent toughness, may experience accelerated wear in high-stress environments. Likewise, high-alumina ceramics, while extremely hard, can crack under severe impact, affecting overall performance.

In recent years, carbide brazed mining wear-resistant plates have performed well in solving wear-resistant problems in high mechanical stress and dynamic load applications, and have become one of the materials that have attracted much attention in the industrial field. Carbide is known for its exceptionally high strength and toughness, which effectively resists breakage and impact, making it ideal for wear-resistant plate manufacturing. In this field, Zhuzhou old craftsmen used unique processes to produce carbide welded mining wear-resistant plates with excellent performance, bringing a technological leap to the industry.

Among the manufacturing materials of cemented carbide welded mining wear-resistant plates, cemented carbide has exerted its unique advantages. Compared with common wear-resistant steel, high-chromium cast iron, and high-aluminum ceramics on the market, cemented carbide not only has excellent wear resistance but also has better impact resistance. This is because cemented carbide has the characteristics of high hardness and high strength, which can work stably in high load and high-speed motion environments, effectively resist external impact forces, and extend the service life of the equipment.

The application fields of mining wear-resistant plates mainly involve mining and mineral processing operations, where wear and impact are the most prominent problems. Carbide welded mining wear plates successfully meet these challenges with their excellent performance. These wear-resistant plates use carbide as the wear-resistant layer and are bonded by vacuum welding to improve fatigue resistance. This innovation solves the problem of poor fatigue resistance of the sulfide layer and enables the carbide welded mining wear-resistant plate to have good performance under high loads, high-speed movements, and extreme environments.

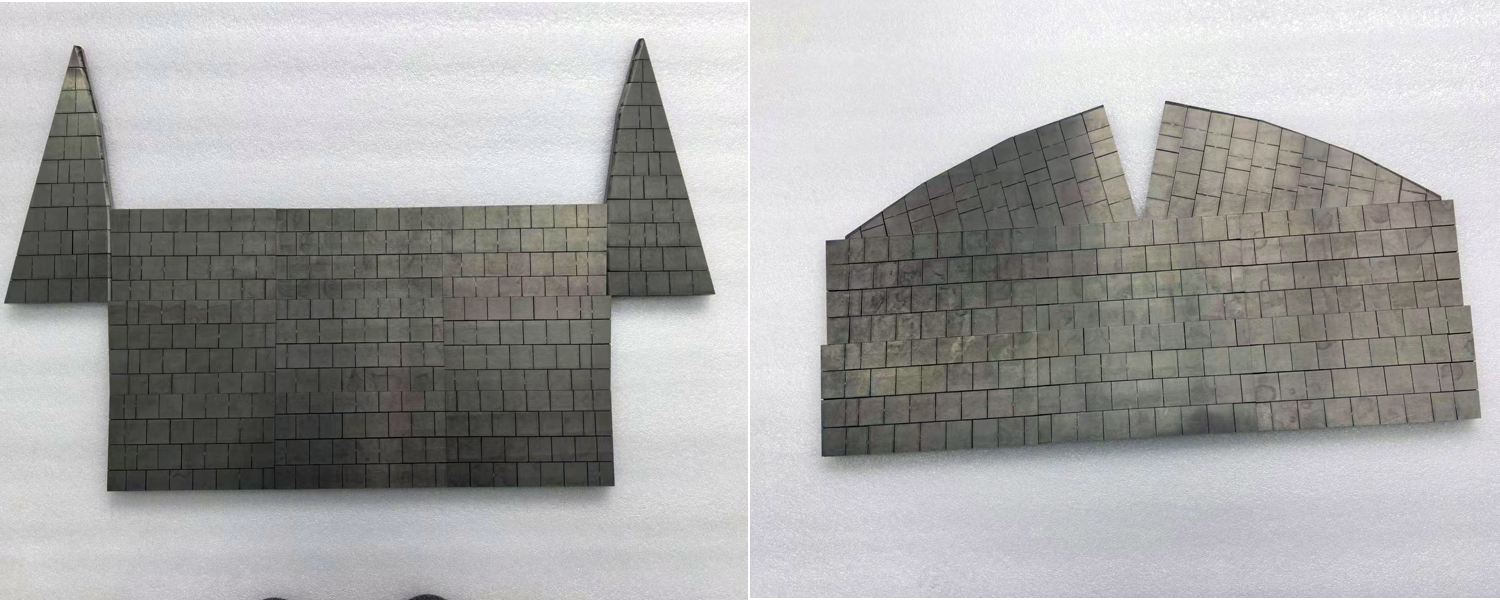

From the perspective of shape and size, carbide welded mining wear-resistant plates can be manufactured into various shapes to adapt to different equipment and application scenarios. Common shapes include liners, funnels, buckets, etc. Among these specific parts, carbide welded mining wear-resistant plates play an important role. In a variety of equipment including crushers, screens, conveyor systems, hoppers, and feeders, these wear-resistant plates can effectively protect vulnerable parts and reduce wear-related maintenance costs, thus improving equipment reliability. and persistence.

Compared with mainstream wear-resistant materials on the market, carbide welded mining wear-resistant plates not only achieve breakthroughs in single performance but also show unique advantages in comprehensive performance. Traditional materials such as wear-resistant steel, high-chromium cast iron, and high-aluminum ceramics may not perform satisfactorily in certain application scenarios. Because hardness and toughness are difficult to balance, the service life is relatively short. Carbide welded mining wear-resistant plates successfully overcome these problems by optimizing the material combination and manufacturing process, providing customers with a more durable and reliable solution.

In the context of fierce market competition, carbide welded mining wear-resistant plates gradually stand out with their unique performance advantages. Through continuous innovation and improvement, Zhuzhou’s old craftsmen have provided the industry with more advanced and reliable wear-resistant solutions. In the future, with the continuous development of technology, it is believed that carbide welded mining wear-resistant plates will play a more important role in a wider range of industrial applications and create greater value for customers.