Why use carbide brazed liners to make refractory brick mold

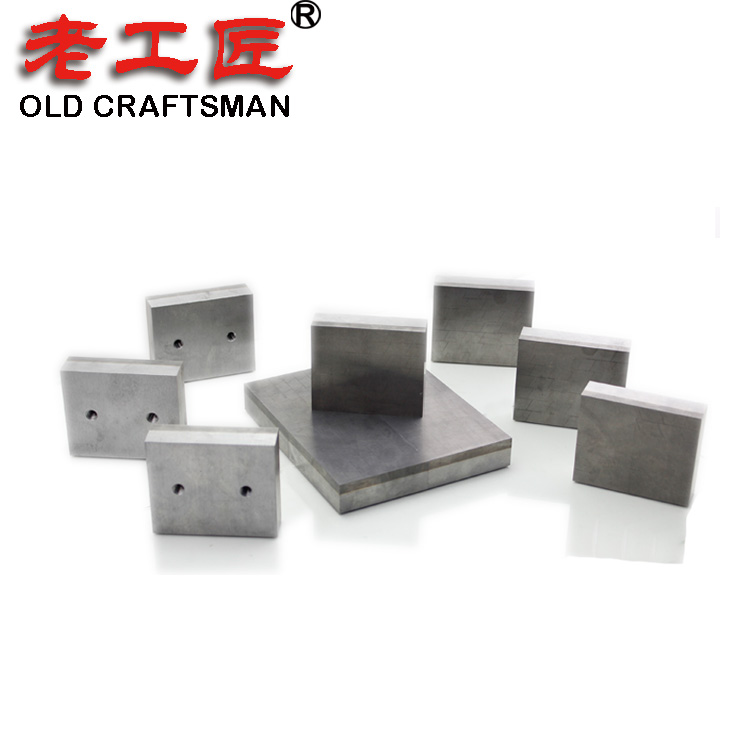

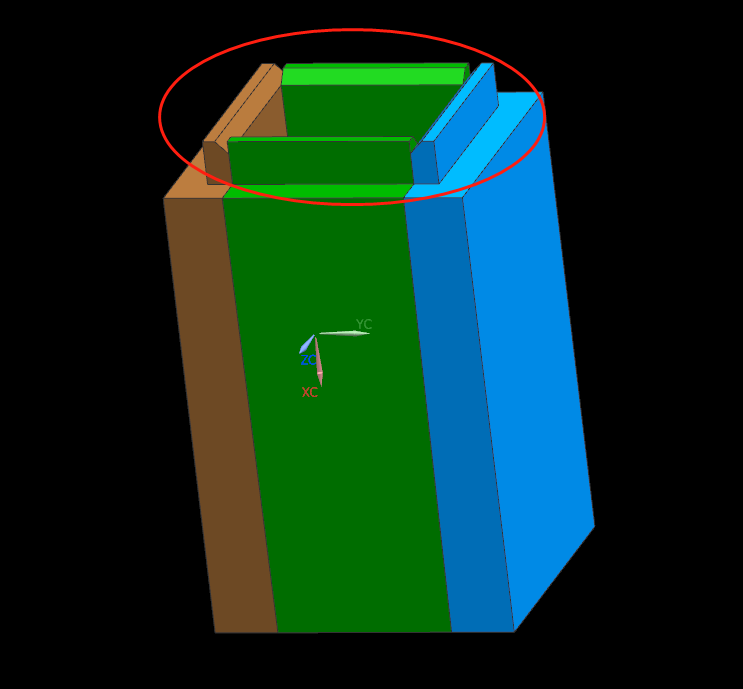

Carbide brazed liner contains two main parts: tungsten carbide tiles and steel backing plate. The main working area for the brazed liner is the tungsten carbide part, the steel backing plate is for easy fix and installation.

As the main working area, tungsten carbide has below features:

1. Hıgh hardness: Tungsten carbide has high hardness. Abrasion resistance and red hardness

The hardness of tungsten carbide can reach 86-93 HRA at room temperature. Equivalent to 69-81 HRC, can maintain high hardness at 900-1000°C, and has excellent wear resistance

2. High strength: High in transverse ruptures strength (bending strength), can bear the high impact

3. High rigidity: It has a high Young’s modulus (difficulty to bend), and excels in rigidity, it is a good material for making mold.

In the current market, refractory brick molds are mainly made of structural steel and tool steel, which are low cost, but have a short lifespan and need frequent replacement, which affects production efficiency. The wear resistance of tungsten carbide is about 15-20 times than that of steel. This advantage greatly prolongs the service life of the refractory brick mold, greatly reduces the frequency of mold replacement, and significantly improves the pressing efficiency of the refractory brick. Because of the different refractory brick materials, Zhuzhou old craftsmen use different cemented carbide grades to produce brazing plates, but the hardness of cemented carbide is guaranteed to be above 91.5HRA.

ZZ Old Craftsman as a vacuum brazed products supplier is mainly using vacuum brazing to make the brazed liner for the refractory brick mold. The main reason for choosing this brazing method is because of obvious characteristics.

Characteristics of the vacuum brazing:

- Brazing strength: The brazing strength of vacuum brazing is better. Brazing strength can be ≥200Mpa

- Large-area brazing: Vacuum brazing is more suitable for large-area brazing, and it is not easy to cause alloy cracking

- Less false brazing: Vacuum brazing is not prone to false brazing. The temperature in the furnace of vacuum brazing is uniform, and the flux is easy to cover the entire brazing area.

- Environmentally friendly: Vacuum brazing is more environmentally friendly and meets the needs of environmental protection.

Why choose ZZ Old Craftsman brazed liners for the refractory mold?

1. Our company has been doing vacuum brazing for 9 years. From the initial experiment to the current mature technique, we have accumulated a lot of experience

2. We communicate closely with customers, and help customers adjust the tungsten carbide parameters and upgrade product structure according to the on-site usage, so that the use effect of the product reach the best state.

3. Our engineers have been in the tungsten carbide manufacture for more than 30 years, and the control of alloys is very precise. At the same time, our company is equipped with complete testing equipment, starting from the testing of carbide powder, testing of press blanks, and testing of finished products after sintering, to ensure that the performance of each batch of products is qualified and stable.

4. We have a complete production line, from ball milling — pressing — sintering — finishing — brazing — post-processing, to control the quality of products from the source

5. At present, our refractory brick molds have been sold in China, to Brazil and Europe, and have been well received very good feedback and repeat orders.