We cordially invite you to join us at EXPOMIN 2025, Latin America’s premier mining exhibition and conference, taking place from April 22-25, 2025, at Espacio Riesco, Santiago, Chile. As a leading provider of carbide wear-resistant solutions for mining, we are excited to showcase our innovative products designed to enhance durability, efficiency, and sustainability in mining operations.

At our booth, you’ll discover cutting-edge hard alloy wear solutions tailored to withstand the toughest mining conditions, reduce downtime, and optimize performance. Our team will demonstrate how our advanced materials and customized designs can address your specific challenges, ensuring cost-effective and eco-friendly outcomes. EXPOMIN 2025 offers a unique platform to explore these solutions while connecting with global industry leaders, with over 1,300 exhibitors and 70,000 visitors expected.

We warmly welcome you to visit us at [Hall 3, Booth No. D14] to discuss potential collaborations and experience our latest innovations firsthand. The event also features insightful conferences on sustainability and digital transformation, providing valuable industry insights.

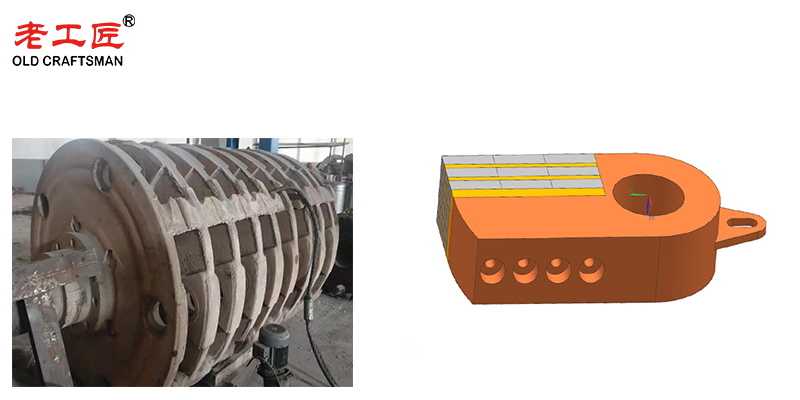

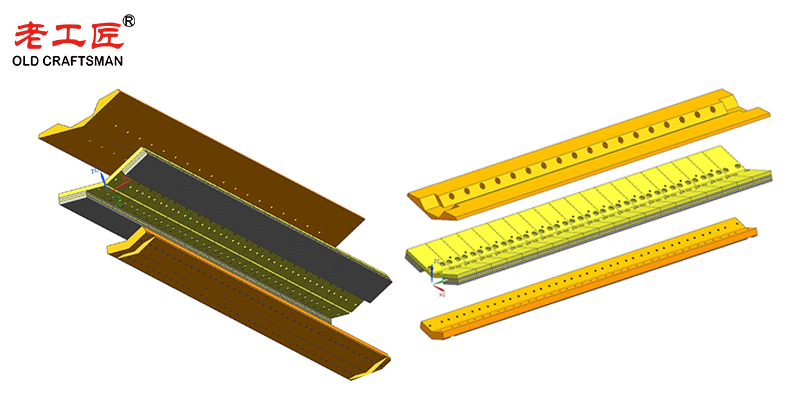

✧ Below is our excellent and very successful tungsten carbide multi-layer composite ore crusher hammer solutions✧

– Replace traditional high chromium and high manganese hammers with our advanced carbide-brazed hammers.

– Offers up to 10-30 times longer service life, engineered for the toughest mining and crushing applications.

Customer Pain Points

- Short Service Life: Lasts only 16-20 hours per side, requiring frequent replacements that disrupt production efficiency.

- Complex Replacement: Time-consuming and labor-intensive to replace, especially in harsh working environments.

- Reduced Efficiency: Worn hammers significantly lower crushing performance, impacting overall output.

Innovative Solutions

- Multi-Layer Carbide Design: Each layer features a specialized carbide grade, delivering exceptional impact resistance and wear protection.

- Precision Brazing: Our unique brazing process ensures a seamless fusion of multi-layer materials, creating a robust and durable bonding surface.

- Customized Structural Optimization: Engineered for high-speed equipment, this design enhances overall hammer performance and adapts to extreme conditions. We offer a tailored, one-client-one-design approach to address your specific challenges based on real-world needs.

Our tungsten carbide wear solutions are widely used in crushing iron ore, copper ore, magnesite, tungsten ore, granite, basalt, limestone, coal, and other ores. We look forward to welcoming you at Expomin 2025 and exploring how our tungsten carbide products can add value to your operations.

To know more about our solutions, visit www.zzcraftsman.com or contact Journey directly at 0086 15273334558. We look forward to meeting you in Santiago and exploring how our solutions can drive your success at EXPOMIN 2025!

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work